What is a Vacuum Ceramic Fiber Chamber Heat Treatment Furnace?

In modern industry, vacuum ceramic fiber chamber heat treatment furnaces are

indispensable due to their excellence in material treatment. As a leading

manufacturer of vacuum heat treatment furnaces, Brother Furnace’s vacuum ceramic

fiber heat treatment furnaces meet the high-temperature treatment needs of a

wide range of industries with their high performance, economy, and

flexibility.

This article will give you a detailed introduction to vacuum ceramic fiber heat treatment furnaces and show how Brother Furnace meets the diverse needs of its customers through innovative equipment design.

The Working Principle of Vacuum Ceramic Fiber Heat Treatment Furnaces

The success of vacuum ceramic fiber chamber heat treatment furnaces involves

several advanced technological elements that ensure high performance and

stability.

Technology for Creating a Vacuum Environment

Vacuum ceramic fiber chamber furnaces can reduce the air pressure inside the furnace to 10 Pa or less using a combination of a highly efficient two-stage rotary vane vacuum pump and a diffusion pump.

This extreme vacuum environment removes gases and impurities from the surface of the material, avoiding oxidation and contamination, thus improving the treatment quality and final properties of the material. The vacuum environment also prevents the material from reacting with air during the heat treatment process, especially important for materials that are susceptible to oxidation.

Core Design of the Heating System

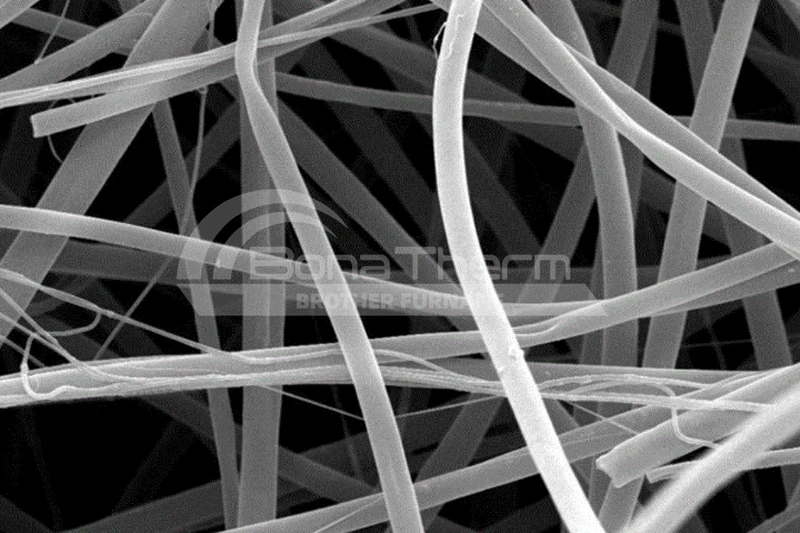

The furnace chamber of the high-temperature vacuum ceramic fiber chamber furnace is made of high-temperature corrosion-resistant alumina ceramic fiber material, which has excellent thermal insulation and high-temperature resistance properties. The heating system uses resistance wires or silicon molybdenum rods, which generate stable and uniform heat using an electric current.

The insulation properties of the ceramic fibers significantly reduce energy loss while providing efficient heating to ensure uniformity and consistency of the material during the high-temperature treatment process.

Innovation in Temperature Control Technology

This machine incorporates an advanced PID temperature control instrument that monitors and regulates the temperature in the furnace chamber in real-time. This control system automatically adjusts the heating power by comparing it with the set value to ensure precise temperature control.

The high accuracy and fast response capability of the temperature sensor make

the process more stable and reduce the impact of temperature fluctuations on the

material.

Flexible Gas Treatment Function

The vacuum ceramic fiber heat treatment furnace of Brother Furnace is designed with an air inlet and an exhaust port, supporting both vacuum extraction and inert gas filling modes. This flexible gas-handling function allows the equipment to be adapted to different process requirements.

For example, if the material needs to be protected from oxidation, the equipment can be filled with an inert gas, such as nitrogen or argon, to protect the surface of the material and preserve its original properties.

Features and Benefits

Excellent Vacuum Performance

The vacuum ceramic fiber chamber heat treatment furnace is capable of achieving ultimate vacuum levels of 10 Pa or less. This high vacuum helps to remove gases and impurities from the surface of the material, improving the purity and quality of the material.

The achievement of ultimate vacuum also effectively prevents oxidation and contamination during the heat treatment process, thus enhancing the final properties of the treated material.

Wide Range of Temperatures

The unit is available with a maximum temperature option of 1200°C or 1700°C, enabling it to meet the needs of different materials and treatment processes.

The high-temperature treatment options allow the furnace to excel in a wide range of high-temperature applications, such as the sintering of ceramic materials and the treatment of refractory metals.

Highly Efficient Heating System

The combination of an alumina ceramic fiber furnace chamber with a resistance

wire or silicon molybdenum rod heating system significantly increases the

heating efficiency and reduces energy consumption. The insulating properties of

the ceramic fiber material significantly reduce heat loss, thus improving energy

efficiency and economy.

Intelligent Control Design

High-temperature vacuum ceramic fiber chamber furnace is equipped with a high-definition touch screen and intelligent PID temperature control instrumentation, with an intuitive and friendly operating interface that simplifies the operating process.

The built-in alarm system can monitor the equipment status in real-time, including the upper limit alarm, deviation alarm, and automatic stop at the end of program operation, which greatly improves the convenience and safety of operation.

Double-water-cooling System

The surface temperature of the furnace shell is controlled below 50°C by a double-water-cooling system, ensuring the safe operation of the equipment and the stability of the operating environment. The efficient water-cooling system prevents overheating and improves the service life and safety of the equipment.

Advanced Design of Vacuum Ceramic Fiber Heat Treatment Furnaces

Brother Furnace's vacuum ceramic fiber heat treatment furnaces combine modern technology and innovative design to advance the state of the art in heat treatment technology:

Advanced Ceramic Fiber Material Application: Alumina ceramic fibers have excellent thermal insulation and high-temperature resistance properties, significantly improving the energy efficiency of the heat treatment process. Compared to conventional materials, ceramic fibers not only increase the heating efficiency of the equipment but also reduce energy consumption and operating costs.

Efficient Vacuum System Configuration: The combination of a two-stage rotary vane vacuum pump and a diffusion pump achieves a highly efficient vacuum environment. This configuration enhances the vacuum level and ensures purity and consistency in material handling. The efficient vacuum system also reduces gas contamination during processing and enhances material quality.

Intelligent Control System: The integrated PLC automatic control system and chiller enhance the automation level of the equipment. The intelligent control system makes the operation of the equipment more efficient and stable, reduces human error, and improves the overall performance of the equipment.

Diversified Application Areas and Their Importance

Vacuum ceramic fiber chamber heat treatment furnace has a wide range of applications covering a variety of industrial needs:

High-temperature sintering of ceramic materials: During the high-temperature

treatment of ceramic materials, the vacuum environment can significantly improve

the densification and strength of the materials. High-temperature sintering

helps to enhance the mechanical properties of ceramic materials, enabling them

to perform well in high-stress applications.

Treatment of ceramic-metal composites: The treatment of ceramic-metal composites at high temperatures helps to improve their mechanical properties and wear resistance. Ceramic fiber vacuum heat treatment chamber furnaces can provide a stable treatment environment to meet a variety of complex industrial needs, ensuring the performance and quality of composite materials.

High-temperature treatment of refractory metals: During high-temperature treatment of refractory metals such as tungsten and molybdenum, the vacuum environment can enhance their physical and chemical properties. A ceramic fiber vacuum heat treatment chamber furnace can provide a stable high-temperature environment to ensure the treatment effect of refractory metals.

Uniform treatment of alloy materials: vacuum ceramic fiber heat treatment furnace can ensure the uniformity and stability of alloy materials. Efficient heating system and precise temperature control ensure the consistency and reliability of alloy materials during treatment.

Brother Furnace: Your Best Choice for Enhancing Material Quality

Vacuum ceramic fiber chamber heat treatment furnaces demonstrate significant

advantages in the field of high-temperature treatment thanks to their excellent

vacuum performance, flexible temperature settings, and efficient heating

systems.

As a professional manufacturer, Brother Furnace’s machines not only meet your high-temperature treatment needs but also provide efficient and reliable solutions. By choosing vacuum ceramic fiber heat treatment furnaces, you will experience the professionalism and innovation of Brother Furnace in heat treatment technology, which will help you achieve greater success in your production business.

Welcome to contact us. You can learn more about our products and discover how Brother Furnace can enhance your productivity and product quality.