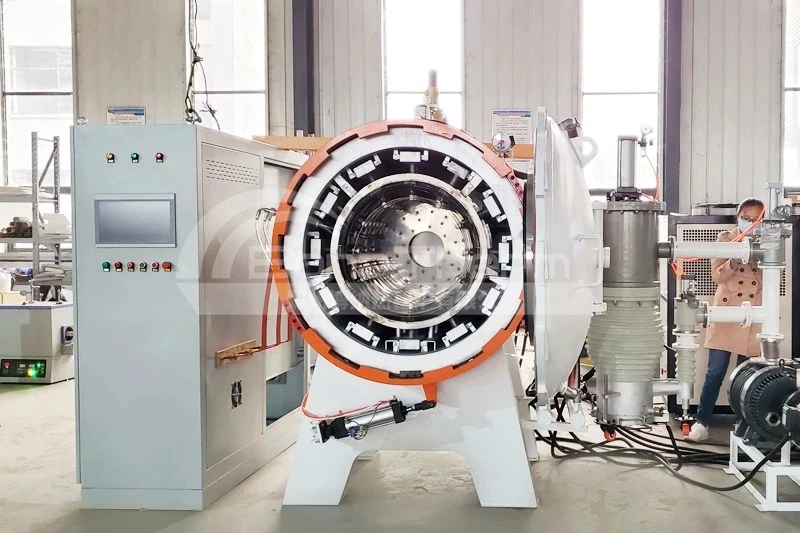

This electric furnace is a very cost-effective vacuum furnace.Low price, simple operation, excellent vacuum effect, good temperature field uniformity.It is used in high temperature vacuum sintering, annealing and tempering of ceramic materials, ceramic metal composites, refractory metals and alloy materials.

Features

● Achieves vacuum levels up to 10Pa with a two-stage rotary vane vacuum pump.

● Option for maximum temperatures of either 1200℃ or 1700℃.

● Equipped with air inlet and exhaust ports for vacuum pumping or inert gas filling.

● Easy operation with pneumatic vacuum valve.

● Ensures vacuum integrity with helium mass spectrometry leak detector, maintaining leakage rate below 0.67Pa/h.

● Utilizes alumina ceramic fiber furnace and either resistance wire or silicon molybdenum rod heating, reducing overall furnace costs.

● Features double water-cooling system, keeping furnace shell surface temperature below 50℃.

● Constructed with high-strength carbon steel, externally electrostatic sprayed for a sleek appearance.

● Offers 50 programmable temperature meter PID adjustments.

● Includes upper limit and deviation alarms, with automatic program shutdown for unattended operation.

Optional accessories

● lIndependent control cabinet

● lPLC automatic control system

● lChiller

● lFurnace rapid cooling system

Technical Parameters

1200 type vacuum heat treatment furnace parameters

model | Maximum temperature(℃) | Operating temperature (℃) | Inner dimension (width*height*depth) ( mm ) | Heating element | Volume (L) | Power ( kW ) | Ultimate vacuum degree |

|---|---|---|---|---|---|---|---|

BR-12VF-1 | 1200 | 1100 | 100*100*100 | Resistance wire | 1 | 1.2 | 10Pa |

BR-12VF-5 | 1200 | 1100 | 150*150*200 | Resistance wire | 4.5 | 3.5 | 10Pa |

BR-12VF-12 | 1200 | 1100 | 200*200*300 | Resistance wire | 12 | 5 | 10Pa |

BR-12VF-36 | 1200 | 1100 | 300*300*400 | Resistance wire | 36 | 12 | 10Pa |

BR-12VF- 96 | 1200 | 1100 | 400*400* 6 00 | Resistance wire | 80 | 18 | 10Pa |

BR-12VF-1 7 5 | 1200 | 1100 | 500*500*700 | Resistance wire | 175 | 30 | 10Pa |

BR-12VF- 324 | 1200 | 1100 | 600*600*900 | Resistance wire | 324 | 50 | 10Pa |

BR-12VF- 768 | 1200 | 1100 | 800*800*1200 | Resistance wire | 768 | 80 | 10Pa |

model | maximum temperature (℃) | Operating temperature (℃) | Inner dimension (width*height*depth) ( mm ) | Heating element | Volume (L) | Power ( kW ) | Ultimate vacuum degree |

|---|---|---|---|---|---|---|---|

BR-12 H VF-1 | 1200 | 1100 | 100*100*100 | Resistance wire | 1 | 1.2 | 7x10-2Pa |

BR-12HVF-5 | 1200 | 1100 | 150*150*200 | Resistance wire | 4.5 | 3.5 | 7x10-2Pa |

BR-12HVF-12 | 1200 | 1100 | 200*200*300 | Resistance wire | 12 | 5 | 7x10-2Pa |

BR-12HVF-36 | 1200 | 1100 | 300*300*400 | Resistance wire | 36 | 12 | 7x10-2Pa |

BR-12HVF- 96 | 1200 | 1100 | 400*400* 6 00 | Resistance wire | 80 | 18 | 7x10-2Pa |

BR-12 H VF-1 7 5 | 1200 | 1100 | 500*500*700 | Resistance wire | 175 | 30 | 7x10-2Pa |

BR-12H VF - 324 | 1200 | 1100 | 600*600*900 | Resistance wire | 324 | 50 | 7x10-2Pa |

BR-12H VF - 768 | 1200 | 1100 | 800*800*1200 | Resistance wire | 768 | 80 | 7x10-2Pa |

1700 type vacuum heat treatment furnace parameters

model | maximum temperature (℃) | Operating temperature (℃) | Inner dimension (width*height*depth) ( mm ) | Heating element | Volume (L) | Power ( kW ) | Ultimate vacuum degree |

|---|---|---|---|---|---|---|---|

BR-17VF-1 | 1700 | 1600 | 100*100*100 | Silicon molybdenum rod | 1 | 1.5 | 10Pa |

BR-17VF-5 | 1700 | 1600 | 150*150*200 | Silicon molybdenum rod | 4.5 | 5 | 10Pa |

BR-17VF-12 | 1700 | 1600 | 200*200*300 | Silicon molybdenum rod | 12 | 8 | 10Pa |

BR-17VF-36 | 1700 | 1600 | 300*300*400 | Silicon molybdenum rod | 36 | 12 | 10Pa |

BR-17VF- 96 | 1700 | 1600 | 400*400*500 | Silicon molybdenum rod | 80 | 30 | 10Pa |

BR-17VF-1 7 5 | 1700 | 1600 | 500*500*700 | Silicon molybdenum rod | 175 | 45 | 10Pa |

BR-17VF- 324 | 1700 | 1600 | 600*600*900 | Silicon molybdenum rod | 324 | 66 | 10Pa |

BR-17VF- 768 | 1700 | 1700 | 800*800*1200 | Silicon molybdenum rod | 768 | 120 | 10Pa |

model | maximum temperature (℃) | Operating temperature (℃) | Inner dimension (width*height*depth) ( mm ) | Heating element | Volume (L) | Power ( kW ) | Ultimate vacuum degree |

|---|---|---|---|---|---|---|---|

BR-17H VF -1 | 1700 | 1600 | 100*100*100 | Silicon molybdenum rod | 1 | 1.5 | 7x10-2Pa |

BR-17HVF-5 | 1700 | 1600 | 150*150*200 | Silicon molybdenum rod | 4.5 | 5 | 7x10-2Pa |

BR-17HVF-12 | 1700 | 1600 | 200*200*300 | Silicon molybdenum rod | 12 | 8 | 7x10-2Pa _ |

BR-17HVF-36 | 1700 | 1600 | 300*300*400 | Silicon molybdenum rod | 36 | 12 | 7x10-2Pa |

BR-17HVF- 96 | 1700 | 1600 | 400*400*500 | Silicon molybdenum rod | 80 | 30 | 7x10-2Pa |

BR-17HVF-1 7 5 | 1700 | 1600 | 500*500*700 | Silicon molybdenum rod | 175 | 45 | 7x10-2Pa |

BR-17HVF- 324 | 1700 | 1600 | 600*600*900 | Silicon molybdenum rod | 324 | 66 | 7x10-2Pa |

BR-17H VF - 768 | 1700 | 1700 | 800*800*1200 | Silicon molybdenum rod | 768 | 120 | 7x10-2Pa |