Revolutionizing Semiconductor Manufacturing with Rapid Thermal Processing Furnaces

In the rapidly evolving landscape of semiconductor manufacturing, the demand

for precision, efficiency, and scalability has never been higher. As

manufacturers strive to meet the needs of next-generation devices, technologies

like rapid thermal processing (RTP) furnaces have emerged as indispensable

tools.

These systems are not only crucial for advanced semiconductor fabrication but also redefine the way high-temperature processes are performed. Brother Furnace is proud to be at the forefront of delivering innovative RTP furnace solutions that cater to the diverse needs of the semiconductor industry.

This article delves into the principles, advantages, applications, and future trends of rapid thermal processing furnaces while emphasizing their transformative potential.

Understanding Rapid Thermal Processing Furnaces

What Is Rapid Thermal Processing?

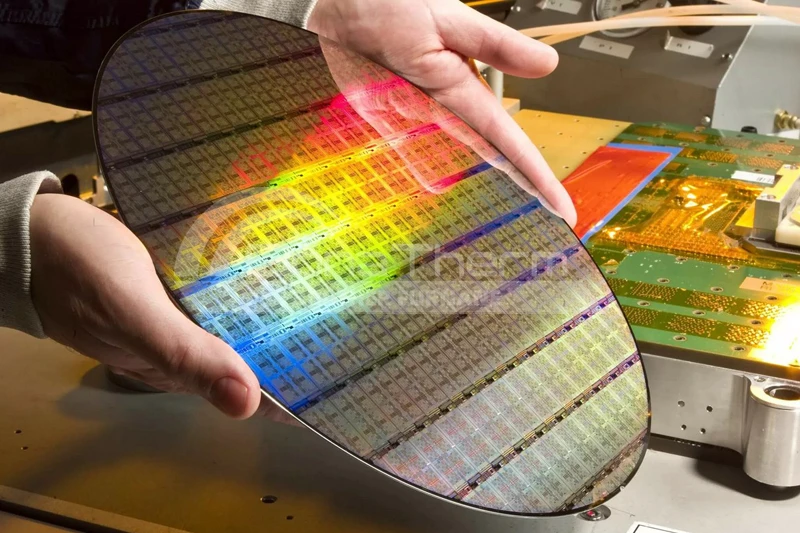

Rapid Thermal Processing (RTP) is a cutting-edge technology that uses

high-intensity energy sources to achieve rapid heating and cooling of silicon

wafers. This technology is pivotal in semiconductor fabrication, where precise

control over temperature is required to enhance device performance and

reliability.

Key Components of RTP Furnaces

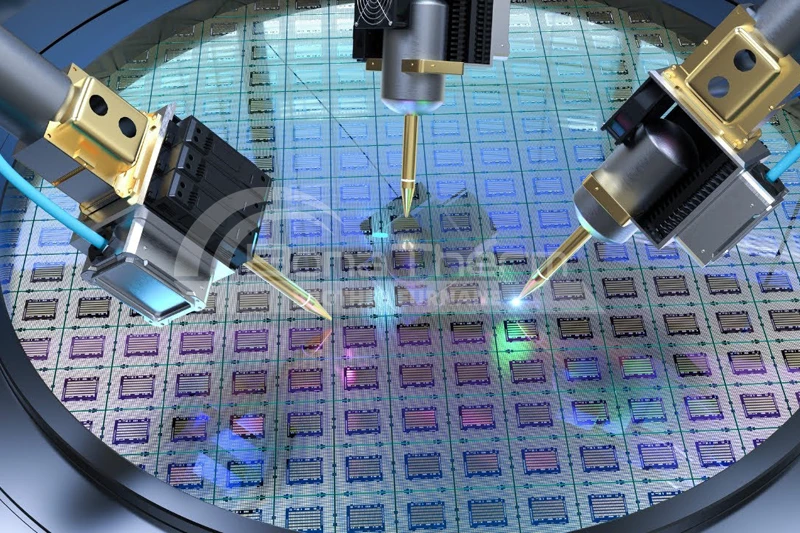

A modern RTP furnace comprises several essential components:

● High-Intensity Heating Systems: These systems provide rapid, uniform heating, critical for achieving consistent results in silicon wafer annealing and thermal oxidation.

● Precision Temperature Control Systems: Advanced sensors and controllers ensure the wafer experiences uniform and precise temperature profiles, even during rapid thermal cycles.

● Controlled Atmosphere Chambers: These allow the furnace to operate in inert, reactive, or vacuum environments, depending on the specific process requirements.

How RTP Differs from Conventional Furnaces

Conventional furnaces rely on slow, bulk heating methods that expose wafers to prolonged high temperatures. In contrast, single-wafer RTP technology targets individual wafers with intense, localized energy, allowing for faster processing and reduced thermal budgets.

This distinction makes RTP furnaces a preferred choice for advanced

semiconductor manufacturing equipment.

Benefits of Rapid Thermal Processing Furnaces

Integrating a rapid thermal processing furnace into your manufacturing processes offers numerous advantages that can significantly enhance operational efficiency and product quality.

1. Improved Process Control and Uniformity

With precision temperature control furnaces, manufacturers can achieve unparalleled uniformity in wafer heating. This level of control is especially critical in processes like RTP for gate dielectric formation, where even minor temperature deviations can compromise device performance.

2. Reduced Thermal Budget

One of the defining features of RTP furnaces is their ability to perform low thermal budget processing. By minimizing the time wafers spend at high temperatures, these systems reduce defects and preserve the integrity of delicate materials, which is vital for cutting-edge semiconductor nodes.

3. Enhanced Device Performance

Rapid thermal annealing solutions improve critical aspects of device performance, including dopant activation, stress relief, and layer uniformity. These enhancements directly translate into more reliable and efficient semiconductor devices.

4. Increased Throughput and Productivity

The fast ramp-up and cool-down capabilities of RTP furnaces ensure shorter

cycle times, enabling manufacturers to process more wafers in less time. This

increased throughput is particularly valuable in high-volume production

environments.

5. Cost-Effectiveness

By optimizing energy consumption and reducing equipment wear, rapid thermal processing furnaces offer a cost-effective solution for advanced semiconductor fabrication. Additionally, their ability to perform multiple processes in a single system reduces the need for additional equipment.

Key Features of Brother Furnsce’s RTP Furnaces

1. High-Intensity Heating Technology

Modern rapid thermal processing furnaces employ advanced lamp systems capable of delivering rapid and uniform heating. These lamps ensure that wafers are heated evenly, eliminating the risk of localized thermal stress.

2. Precision Temperature Control

Accurate temperature control is a hallmark of Brother Furnace’s technology. Advanced sensors and algorithms enable precise adjustments, ensuring consistent results even in complex processes like thermal oxidation equipment applications.

3. Controlled Gas Flow Management

Managing gas flow within the furnace chamber is critical for maintaining the

desired atmosphere. Whether inert, reactive, or vacuum, the ability to control

gas flow ensures optimal process conditions.

4. Process Monitoring

Real-time monitoring tools provide invaluable insights during processing. By tracking variables such as temperature, gas flow, and wafer conditions, manufacturers can fine-tune parameters for optimal outcomes.

Applications of Rapid Thermal Processing Furnaces

The versatility of RTP furnaces extends across various industries, making them a cornerstone of high-tech manufacturing.

1. Semiconductor Device Fabrication

Core processes in semiconductor device fabrication equipment, such as dopant activation, stress relief, and junction formation, rely heavily on RTP technology. Its precision and speed make it ideal for producing high-performance devices.

2. Solar Cell Manufacturing

In the renewable energy sector, rapid thermal processing furnaces are essential for fabricating high-efficiency solar cells. These furnaces enable rapid processing of silicon wafers, improving the cost-efficiency of solar panel production.

3. Research and Development

In materials science and semiconductor research, controlled atmosphere RTP

furnaces are invaluable tools for exploring new materials and process

innovations.

Choosing the Right RTP Furnace for Your Business

Selecting the ideal rapid thermal processing furnace involves careful consideration of your specific manufacturing needs. Here are some key factors to guide your decision:

1. Application-Specific Requirements

Ensure that the furnace supports your intended processes, whether it's silicon annealing systems, thermal oxidation equipment, or other specialized applications.

2. Customization Options

Many manufacturers, including Brother Furnace, offer tailored solutions to address unique fabrication challenges. Customized systems can enhance productivity and process efficiency.

3. Support and Maintenance

Reliable technical support and comprehensive maintenance services are essential for minimizing downtime and maximizing the lifespan of your equipment.

Brother Furnace specializes in providing semiconductor device fabrication

equipment that combines advanced technology with unmatched reliability, ensuring

that our clients achieve their production goals.

Conclusion

In the competitive world of semiconductor manufacturing, staying ahead requires adopting technologies that deliver precision, efficiency, and scalability. rapid thermal processing furnaces represent a game-changing solution, offering unparalleled benefits for high-temperature materials processing.

By investing in RTP solutions from Brother Furnace, manufacturers can enhance productivity, ensure superior device quality, and reduce operational costs.

If you’re ready to revolutionize your operations with state-of-the-art rapid thermal processing furnaces, contact Brother Furnace today. Let us help you unlock new possibilities in semiconductor manufacturing equipment and take your business to the next level.