Rapid Thermal Annealing Furnaces: Transforming Semiconductor Manufacturing with Precision and Speed

In the fast-evolving world of semiconductor manufacturing, precision and

efficiency are paramount. As semiconductor devices continue to shrink and

increase in complexity, manufacturers require tools to meet stringent processing

demands while maintaining high throughput.

Enter the rapid thermal annealing furnace, a revolutionary tool designed to meet the specific needs of modern wafer processing.

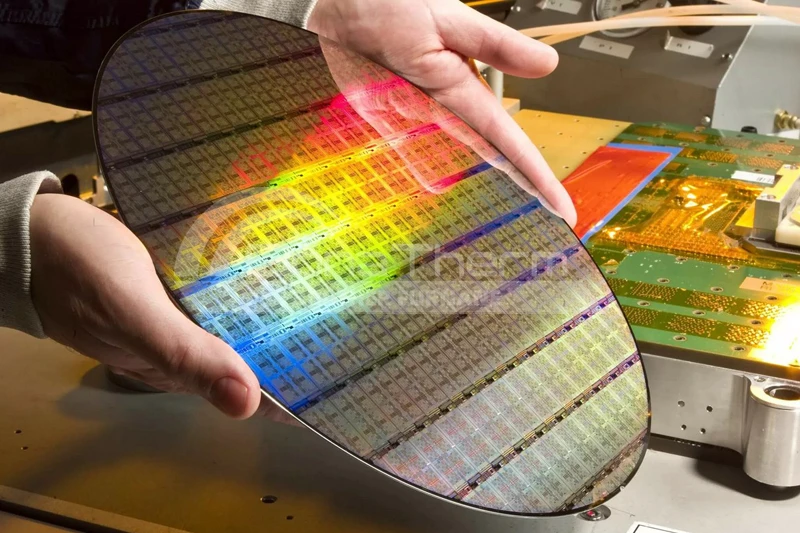

Rapid thermal annealing (RTA) allows for controlled heating and cooling of semiconductor wafers at fast rates, often reaching target temperatures within seconds. This controlled thermal environment is crucial in achieving the desired properties for semiconductor devices.

Given the growing demand for high-temperature furnaces and advanced annealing equipment capable of delivering reliable, repeatable results, RTA technology has become a core solution in thermal processing solutions.

In this article, Brother Furnace will explore the myriad benefits of RTA furnaces, their essential features, and how they redefine standards in semiconductor annealing and other precision-driven industries.

We’ll also discuss factors to consider when selecting an RTA furnace and

delve into the future trends shaping this technology. For manufacturers in any industry, understanding these factors is essential in

making informed investments in rapid thermal annealing furnaces.

Benefits of Using Rapid Thermal Annealing Furnaces

Rapid thermal annealing furnaces offer several key advantages over traditional wafer heating systems, especially in industries that require precision and consistency:

Improved Processing Speed: One of the most significant advantages of RTP (Rapid Thermal Processing) is its high-speed operation. Conventional annealing processes may take hours, but RTA can reach target temperatures within a short period, which greatly reduces processing time. This capability is precious in wafer processing, where high throughput is essential.

Enhanced Temperature Control and Uniformity: The latest furnace temperature control technologies ensure uniform temperature distribution across the wafer surface, which minimizes the risk of thermal gradients that could lead to defects. For silicon wafer annealing and other precision processes, maintaining this uniformity is crucial for achieving high-quality results.

Reduced Thermal Budget: Reducing the exposure of wafers to prolonged high temperatures minimizes potential damage to the materials, especially thin films and sensitive semiconductor structures. Rapid thermal treatment allows for precise and controlled thermal exposure, which is beneficial for optimizing the thermal budget and reducing wear on materials over time.

Increased Wafer Throughput: Given the fast processing capabilities of RTP

systems, manufacturers can increase the number of wafers processed per day, thus

achieving higher productivity levels. This increased throughput is vital in

industries where rapid production cycles drive profitability.

Better Quality Control in Semiconductor Manufacturing: By providing precise control over thin film deposition, thermal oxidation, and dopant activation, the furnaces help ensure consistent, high-quality production standards. This level of control minimizes variations in semiconductor annealing, ultimately improving yield rates and reducing material waste.

Key Features to Look for in RTA Furnaces

When evaluating an RTA furnace for purchase, it’s important to consider several features to ensure that the system aligns with production needs and quality standards:

Temperature Range and Ramp Rates: Different applications require different temperature ranges and ramp rates. Brother Furnace offers diverse configurations, but for high-speed, high-precision applications, the temperature ramp rate can greatly impact processing time and uniformity.

Chamber Design and Gas Flow Control: The furnace chamber must support optimal gas flow control to maintain the desired atmosphere and minimize contamination risks. This feature is particularly important for processes requiring an inert or controlled atmosphere, such as thermal oxidation or silicon wafer annealing.

Process Automation and Recipe Management: Automation is essential for

high-volume production environments. Many RTA systems feature programmable

recipe management, allowing operators to set and replicate specific heating

profiles for consistent results. This automation is invaluable for semiconductor

manufacturing, where repeatability is a key quality metric.

Applications in Various Industries

Rapid thermal annealing furnaces play a vital role in semiconductor manufacturing and are also used in other fields that require precise thermal processing:

Semiconductor Manufacturing: RTA furnaces are essential for dopant activation, silicide formation, thermal oxidation, and contact alloying, all of which are critical steps in semiconductor fabrication.

Solar Cell Production: RTA technology is used in solar cell production to anneal and process materials that enhance photovoltaic efficiency.

Optoelectronics and Advanced Packaging Technologies: The high precision of RTA systems is ideal for the production of LEDs, lasers, and other optoelectronic devices that demand temperature stability and control.

Considerations When Choosing an RTA Furnace

Selecting the right furnace depends on various production requirements and goals. Key factors to consider include:

Production Volume Requirements: Understanding production volume helps

determine the size, speed, and capabilities of the furnace needed.

Specific Process Needs: Each thermal process may have different requirements for temperature, ramp rates, and atmospheric control. The selected furnace should meet these specific needs, whether for thermal oxidation, dopant activation, or another thermal processing solution.

Integration with Existing Manufacturing Lines: For seamless operation, compatibility with current manufacturing systems is essential. Ideally, the RTA furnace should integrate well with existing automation and control systems.

Total Cost of Ownership (TCO): While initial investment costs for high-temperature furnaces can be substantial, the long-term operational efficiency, reduced thermal budget, and increased throughput contribute to a lower TCO, making RTA a cost-effective option.

Vendor Support and Service Capabilities: Quality support ensures that any potential issues are addressed promptly, minimizing downtime and extending equipment life. Brother Furnace, an annealing furnace supplier with strong service capabilities is your preferred partner.

Conclusion

In today’s fast-paced semiconductor industry, rapid thermal annealing furnaces are indispensable for achieving precision, speed, and consistency. With benefits like increased throughput, better temperature control, and enhanced quality, annealing furnaces represent a significant advancement in thermal processing solutions.

As a leading manufacturer, Brother Furnace is committed to delivering

reliable, high-quality annealing equipment to support industries in achieving

their processing goals.

For those in search of rapid thermal annealing furnaces that can meet evolving demands in semiconductor manufacturing and beyond, an investment in a rapid thermal annealing furnace is a step toward greater efficiency, lower costs, and superior product quality.

Welcome to contact us to explore our range of thermal processing solutions and find the right fit for your production needs.