Which Atmospheres Can Be Used for Heat Treatment?

- By: Brother Furnace

- 2024-10-02 03:03

Heat treatment is a critical process in manufacturing, where heating and

cooling are used to improve the properties and microstructure of materials.

Whether in the automotive, aerospace, electronics, or medical industries, heat

treating plays a key role in improving the strength, wear resistance, and other

physical properties of materials. Choosing the right atmosphere for heat

treatment can directly affect the quality and performance of the final

product.

In this article, Brother Furnace will introduce you to the various atmospheres commonly used in the heat treatment process, and analyze their characteristics, applicable scenarios, and corresponding advantages to help you make an informed choice.

What is Heat Treatment

Heat treatment is a process that changes the microstructure and mechanical

properties of a material by heating, holding, and cooling. The process consists

of several steps, such as annealing, quenching, and tempering, each of which

requires specific temperature and atmosphere control. The purpose of heat

treatment is to optimize the strength, toughness, wear resistance, and other

physical properties of a material to meet a variety of industrial needs.

What are the Heat Treating Atmospheres

Heat-treating atmospheres can be categorized into a variety of types, each with a unique role and application scenario. Below we will discuss the characteristics of each atmosphere and its applicability.

1. Air Atmosphere

Characteristics: The air atmosphere is the most common heat treatment atmosphere. However, due to the presence of oxygen, materials are easily oxidized at high temperatures, especially iron-based materials.

Application: It is usually used for materials that are not highly sensitive to oxidation, such as certain alloy steels and aluminum alloys. During the annealing and hardening process, air atmosphere can effectively enhance the mechanical properties of materials.

2. Inert Atmosphere

Characteristics: The inert atmosphere usually uses argon or nitrogen, which can effectively prevent the oxidation of materials and is suitable for materials sensitive to oxygen.

Application: It is suitable for heat treatment of high-temperature

superconducting materials, titanium alloys and so on. In the processing of these

materials, the inert atmosphere can maintain the purity of the material and

avoid chemical reactions.

3. Reduction Atmosphere

Characteristics: A reduction atmosphere can remove the oxidized layer on the surface of the material, usually using hydrogen or carbon monoxide. In the heat treatment process, this atmosphere can effectively improve the surface quality of the material.

Application: Reduction atmosphere is suitable for materials requiring high-temperature heat treatment, especially high alloy steel and tool steel. This atmosphere helps to improve the toughness and strength of the material.

4. Vacuum Atmosphere

Characteristics: Vacuum atmosphere is heat treatment under vacuum conditions, eliminating the effects of the atmosphere on the material. It prevents oxidation, decarburization, and other atmosphere-induced chemical reactions.

Application: It is suitable for materials with extremely strict atmosphere

requirements, such as high-temperature alloys and super-hard materials. Vacuum

heat treatment ensures high product quality and consistency.

Influence of Atmosphere Selection on Heat Treatment

When using an atmosphere sintering furnace, the selection of a suitable heat treatment atmosphere is critical to the performance of the final product. The choice of different atmospheres directly affects the following aspects:

1. Oxidation and Reduction of Materials

In an air atmosphere, materials are susceptible to oxidation, especially at high temperatures. This can lead to a reduction in material properties, whereas in an inert or reducing atmosphere, this problem can be effectively avoided and the original properties of the material maintained.

2. Improvement of Material Surface Quality

The influence of the atmosphere on the surface quality of materials should not be underestimated. Vacuum atmosphere can eliminate surface oxides and keep the surface smooth. In the reducing atmosphere, the oxide layer on the surface of the material can be removed, improving the surface hardness and wear resistance.

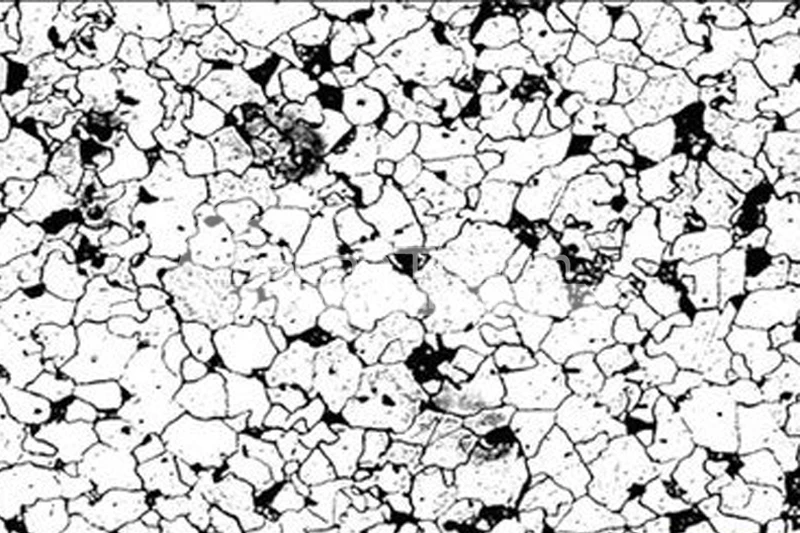

3. Microstructure

The choice of atmosphere also affects the microstructure of the material,

which in turn affects its mechanical properties. For example, the use of an

inert atmosphere can slow down grain growth, thus increasing the strength of the

material.

Specific Application Cases of Heat Treatment Atmosphere Furnaces

Below are some specific application cases. Brother Furnace will show you the functions and advantages of different atmospheres in heat treatment.

Heat Treatment of Steel

Air and reducing atmospheres are commonly used for heat treatment of steel. In the quenching process of steel, air atmosphere can provide the necessary cooling rate, but in the heat treatment of high alloy steel, the use of reducing atmosphere can improve the wear resistance and strength of the material.

Heat Treatment of Aluminum Alloys

When heat-treating aluminum alloys, an inert atmosphere is often used to avoid oxidation. As an inert atmosphere, argon not only prevents oxidation but also maintains the microstructure of the aluminum alloy, ensuring its strength and toughness.

Heat Treatment of Titanium Alloys

Titanium alloys are extremely sensitive to oxygen. Therefore, heat treatment of them with an inert atmosphere (e.g. nitrogen) can ensure their properties. At high temperatures, oxidation of titanium alloys leads to increased brittleness, so maintaining an inert atmosphere is critical.

Heat Treatment of Electronic Components

In the electronics industry, the use of vacuum atmosphere furnaces for heat

treatment can avoid oxidation and chemical reactions of materials and ensure

stable performance of electronic components. This atmosphere is usually used for

heat treatment of high-precision electronic components

Brother Furnace: A Professional Manufacturer of Atmosphere Furnaces

As a specialized manufacturer of atmosphere sintering furnaces, Brother Furnace has accumulated a wealth of experience and technology in the field of atmosphere heat treatment.

High performance: Brother Furnace is designed to increase heat treatment efficiency, shorten processing cycles, and reduce energy consumption.

Precise control: Our atmosphere sintering furnaces are equipped with an advanced temperature control system, which can precisely control the temperature and atmosphere during the heat treatment process, providing customers with stable processing conditions.

Versatility: The atmosphere furnace supports a variety of atmosphere options,

including nitrogen, argon, hydrogen, etc., to meet the needs of different

materials.

High reliability: The atmosphere furnaces have been rigorously tested to ensure high stability and reliability under a variety of operating conditions.

Customized service: Brother Furnace can also provide you with customized heat treatment solutions, able to design suitable atmosphere furnaces to optimize the production process according to customers' specific needs.

Using the Proper Atmosphere is the Key to an Atmosphere Sintering Furnace

In the heat treatment process, choosing the right atmosphere is critical to the performance of the material. Different atmospheres not only affect the oxidation, reduction, and surface quality of the material but also determine the microstructure and mechanical properties of the final product.

With its efficient, precise, and reliable atmosphere furnaces, Brother Furnace is committed to providing customers with the best heat treatment

solutions to help them succeed in their respective fields.

By understanding the characteristics and applications of various atmospheres, you can better select the right heat treatment atmosphere for your material. If you are interested in Brother Furnace's vacuum atmosphere furnaces, please feel free to contact us.

Brother Furnace will be happy to provide you with professional service and support to make your heat treatment process more efficient and successful.