Vacuum Hot Press Furnace: The Driving Force of Modern Manufacturing Industry

In the field of materials science and engineering, vacuum hot press furnace

has become an indispensable and important equipment with its unique working

principle and wide application prospects.

The core value of the vacuum hot press furnace lies in its ability to promote the diffusion and rearrangement of atoms or molecules inside the material under the joint action of high temperature and high pressure in a vacuum environment by eliminating the gases and impurities in the material, to realize the densification and optimization of the material's properties.

The use of vacuum hot pressing sintering furnace, not only helps to improve the mechanical strength, abrasion resistance, corrosion resistance, and other key indexes of the material but also effectively prevents the material from reacting with oxygen and other gases in the air at high temperature, avoiding the oxidation and contamination of the material and ensuring the quality and stability of the material.

As a professional manufacturer of vacuum hot press furnaces, Brother Furnace is committed to providing customers with the most excellent performance and design of vacuum high-temperature hot press furnaces.

At present, Brother Furnace’s vacuum hot press furnace has been used in many industries and has received a large number of positive comments from customers.

Why vacuum hot press furnaces can get a lot of praise in the manufacturing

industry? Here are the core secrets of the vacuum hot press furnace.

The Operating Principle of Vacuum Hot Press Furnace

As a kind of hot pressing equipment under a vacuum environment, the vacuum hot pressing sintering furnace integrates vacuum technology, high-temperature heating technology, and a pressure control system, which is able to achieve precise processing and optimized treatment of materials under severe process conditions.

1. Establishing a Vacuum Environment

In the vacuum hot pressing furnace, the vacuum pump system pumps the air out of the furnace chamber to create a vacuum environment with low oxygen and low atmosphere interference. The vacuum environment can effectively reduce the reaction between the material and oxygen and other gases during high-temperature treatment, prevent material oxidation and contamination, and thus improve the purity and performance of the material.

2. High Temperature Heating

The heat treatment vacuum hot press furnace adopts an advanced heating system to heat the material with precisely controlled high-temperature heating elements. The heating system selects appropriate heating elements according to the hot pressing requirements of different materials and uniformly heats the material to the required temperature in the furnace chamber.

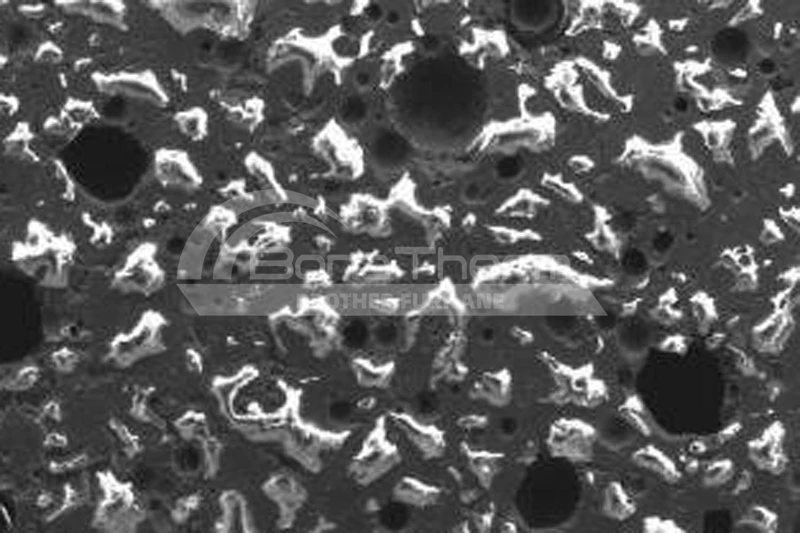

This process promotes sintering, densification, and phase transformation of the material and improves the microstructure and macroscopic properties of the material.

3. High Pressure Processing

During the heating process, the vacuum hot press furnace applies high

pressure through the pressure control system to compact the material. The high

pressure can further improve the density and uniformity of the material,

eliminate internal defects and pores, and improve the mechanical properties and

durability of the material.

4. Cooling and Curing

After the material has been processed for a certain period in a high-temperature and high-pressure environment, the cooling system in the vacuum hot press furnace of the Brother Furnace rapidly reduces the temperature so that the material is gradually cooled and cured.

The control of the cooling process is equally important, as it prevents stress and deformation of the material during the cooling process and ensures the quality and stability of the final product.

Why the Vacuum Hot Press Furnace Can Beat the Competitors

With the rapid development of science and technology, the requirements for material properties continue to improve. Materials such as inorganic materials, cemented carbides, functional ceramics, and powder metallurgy show a wide range of potential applications in several industries due to their excellent physical and chemical properties.

However, the processing of these materials is often very complex, with extremely stringent requirements for temperature, pressure, and atmosphere. Conventional equipment is often unable to meet these stringent requirements, resulting in limited material properties and high production costs.

Hot press sintering furnace is well suited for sintering these materials. It combines high-temperature heating, vacuum control, pressure regulation, and other functions in a single unit, which enables the materials to be processed finely under extreme conditions, significantly improving their properties and quality.

Flexible heating system

Brother Furnace's vacuum hot-pressing furnace adopts an advanced heating

system design, which can flexibly adjust the heating elements according to the

hot-pressing temperature requirements of different materials.

For low-temperature sintering, the resistance wire module is used to ensure uniform temperature and easy control; while for high-temperature sintering, it is switched to a graphite heater to ensure stable heating under a high-temperature environment. This heating system not only improves the adaptability and flexibility of the equipment but also extends the service life of the equipment.

Adjustable Pressure Control System

Pressure control is one of the key factors affecting the sintering quality of materials. High-temperature hot press furnaces are equipped with a precise pressure control system that allows the pressure value to be adjusted arbitrarily within a range of up to 5 tonnes.

In addition to this, precise control is possible for small samples and large batches. In addition, the system is equipped with an overload protection function to ensure the safety of the equipment and the operator.

Highly Accurate Ranging and Positioning

To ensure accurate material positioning during the hot pressing process,

Brother Furnace's vacuum hot press furnaces use a scale ranging technology to

achieve ranging accuracy within 0.02mm. The system is able to monitor the change

of material position in the furnace in real-time and adjust the pressure and

heating parameters to improve the molding accuracy and reduce the scrap rate and

production cost.

Intelligent Control System

The control system of the hot press sintering furnace combines PLC and touch screen technology to achieve closed-loop control of key components such as temperature control, voltage regulator, and high current transformer.

The touchscreen interface enables the operator to easily set process parameters, monitor equipment operating status, and has data logging and troubleshooting functions to enhance equipment reliability and maintenance efficiency.

Brother Furnace: Professional Vacuum Hot Press Furnace Manufacturer

Brother Furnace’s vacuum hot press furnaces represent the cutting edge of

material handling technology. Brother Furnace is committed to significantly

improving production efficiency through intelligent and automated operation.

With its excellent design concepts and advanced technological features, the vacuum hot pressing furnace not only meets the extensive needs of higher education institutions, scientific research institutes, and high-end manufacturing enterprises but also provides strong support for their technological innovation and productivity enhancement.

As a professional vacuum hot press furnace manufacturer, Brother Furnace is committed to providing customers with the best quality solutions to meet the ever-changing market demand. Brother Furnace is not only a pioneer in technological innovation but also a reliable partner in promoting the development of the industry.

Choosing the vacuum hot press furnace from Brother Furnace is choosing an efficient, intelligent, and reliable future.

Brother Furnace welcomes your inquiry and cooperation!