Vacuum Graphite Carbon Tube Furnaces: A Comprehensive Overview

In modern industry and scientific research, vacuum graphite carbon tube furnaces, as advanced heating equipment, have become a core part of many

high-end technology applications.

As a professional manufacturer of vacuum graphite carbon tube furnaces, Brother Furnace is committed to providing the best quality products to meet the needs of different industries for high-temperature treatment.

In this article, we will discuss the knowledge of vacuum graphite carbon tube furnaces to help you fully understand this equipment.

What is a Vacuum Graphite Carbon Tube Furnace?

High-temperature vacuum graphite carbon tube furnace is a kind of high-temperature furnace of cyclic operation type, which is mainly used as a heating element through graphite tubes, sintering or heat treatment of metal materials and inorganic non-metallic materials under vacuum or protective atmosphere.

The furnace is especially suitable for high-temperature treatment of

materials to obtain higher purity and performance. It is widely used in the

fields of material science, metallurgy, and roasting and purification of optical

materials.

Working Principle

Graphite Heating Element

The core of the graphite carbon tube furnace is graphite heating elements. With its excellent thermal conductivity and high-temperature stability, graphite can provide a uniform and stable heating environment.

Graphite's excellent electrical conductivity enables it to efficiently convert electrical energy into heat energy at high temperatures and maintain a uniform temperature inside the furnace chamber. Brother Furnace's vacuum graphite carbon tube furnaces can operate at a maximum temperature of 2400°C, which makes them capable of meeting the most demanding high-temperature processing needs.

Vacuum Environment

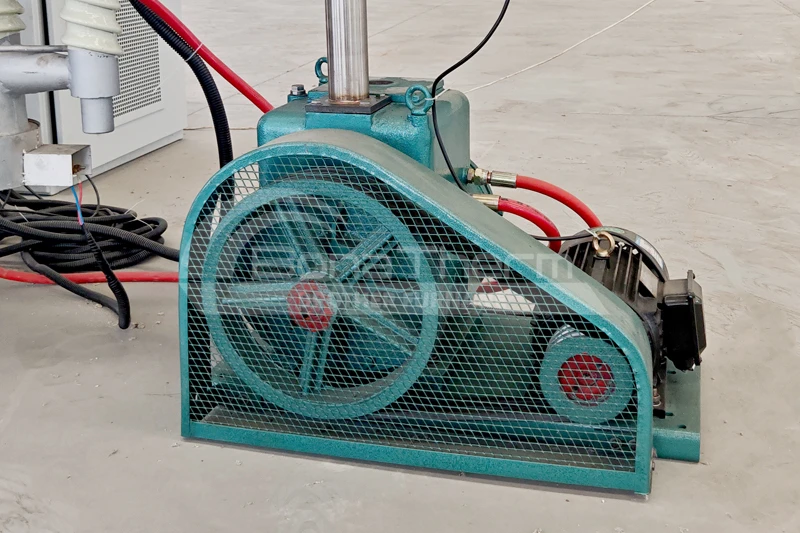

The vacuum graphite carbon tube furnace has a built-in sophisticated vacuum pump system that maintains a high vacuum environment inside the furnace chamber, which not only prevents material oxidation but also reduces possible gas contamination.

The vacuum environment helps to improve the purity of the processed

materials, which is especially suitable for processing optical materials and

high-purity metals. By precisely controlling the vacuum level, users can achieve

higher-quality heat treatment results.

High-Temperature Control System

To ensure precise temperature control, Brother Furnace has equipped the vacuum graphite carbon tube furnace with an advanced temperature control system. The combination of tungsten rhenium thermocouple and infrared thermometer can realize fast and accurate temperature measurements.

The tungsten rhenium thermocouple has excellent high-temperature stability and durability, and can automatically enter and exit the furnace chamber for measurement, while the infrared pyrometer provides real-time temperature monitoring.

The PLC automatic control system ensures the automation and precise control of the entire heating process, which greatly improves the convenience and safety of operation.

The Highlights of the Vacuum Graphite Carbon Tube Furnace

Dual water-cooled construction: The furnace shell is made of polished stainless steel on the inside and carbon steel on the outside. The double-water-cooled construction dissipates heat efficiently, thus lowering the external temperature of the equipment and prolonging its service life. In addition, this design contributes to the overall safety and energy efficiency of the vacuum graphite carbon tube furnace.

Observation window: The furnace shell is equipped with an observation window,

which allows you to observe the heating situation inside the furnace at any time

during operation. This design greatly improves the convenience and safety of

operation.

High-definition touch screen interface: Brother Furnace has equipped the carbon tube furnace with a high-definition touch screen and built-in operating system developed by Brother Furnace, which is simple and intuitive to operate. You can conveniently carry out various settings and monitoring.

Optional accessories: In order to meet the needs of different customers, Brother Furnace provides a variety of optional accessories, including water chillers and graphite crucibles. These accessories can further enhance the function and application range of the furnace.

Wide Application of Vacuum Graphite Carbon Tube Furnace

For its high temperature, high precision, and excellent vacuum environment, the vacuum graphite carbon tube furnace is widely used in many high-tech fields.

Materials Science

In materials science, vacuum graphite carbon tube furnaces are used to

research and develop new materials, including high-performance ceramics,

superconducting materials, and nanomaterials.

As these materials need to be stabilized at extremely high temperatures during the manufacturing process, the high temperatures and precise control capabilities of vacuum graphite carbon tube furnaces provide ideal conditions for material synthesis. By performing heat treatment in a vacuum environment, researchers can effectively control the crystal structure of materials and improve their properties.

Metallurgical Industry

In the metallurgical industry, vacuum graphite carbon tube furnaces are mainly used for high-temperature sintering and heat treatment of metals.

Particularly in the production of high-strength alloys, cemented carbides, and special metal materials, vacuum graphite carbon tube furnaces ensure that metals are heated uniformly in an oxidation-free environment, optimizing the physical and chemical properties of the materials. This is particularly important for aerospace and automotive manufacturing as well as the production of high-end tools and molds.

Optical Materials

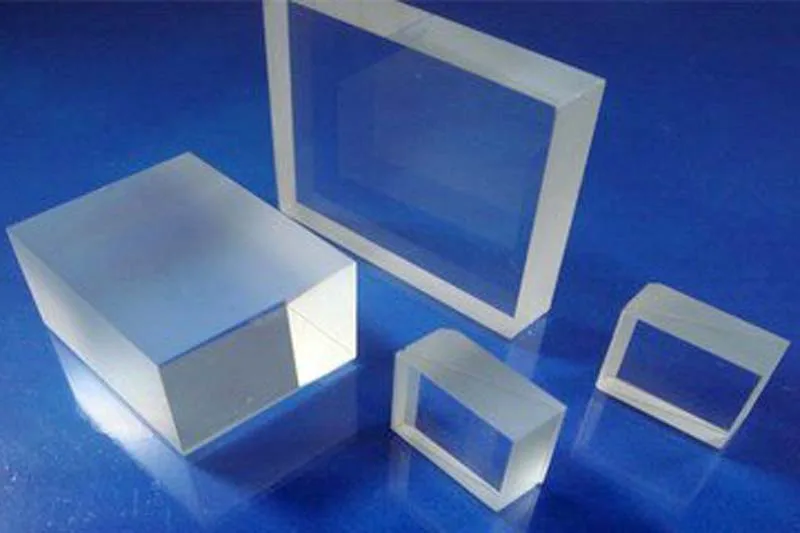

The roasting and purification of optical materials such as optical glass and

crystals at high temperatures is a critical step in ensuring their high

performance. The high temperatures and vacuum environment of vacuum graphite and

carbon tube furnaces remove impurities from optical materials and improve their

optical properties.

This process not only improves the transparency and homogeneity of the material but also reduces defects caused by oxidation or contamination, which is critical for the production of high-precision optical devices.

Electronic Devices

The manufacture of electronic devices involves precision material processing, such as the sintering of semiconductor materials and high-temperature treatment of conductive materials. Graphite carbon tube furnaces provide a stable high-temperature environment for these processes, ensuring the quality and performance of semiconductor materials.

Especially in the manufacture of high-performance integrated circuits and advanced electronic components, the high vacuum and precise temperature control system inside the furnace can effectively avoid material oxidation and contamination.

Chemical Synthesis

In the field of chemical synthesis, vacuum graphite carbon tube furnaces

are used to synthesize high-purity chemicals and catalysts. By synthesizing in a

vacuum environment at high temperatures, the reaction process can be controlled

and side reactions avoided, resulting in higher purity products. This is

important for the production of fine

chemicals.

Material Annealing and Regeneration

For the annealing process of some high-tech materials and composites, vacuum graphite carbon tube furnaces provide the high temperature and vacuum environment necessary to remove stresses and defects within the material. This process helps to improve the mechanical properties and stability of the material.

These application areas of vacuum graphite carbon tube furnaces demonstrate their importance and wide applicability in modern technology.

As a professional manufacturer of vacuum graphite furnaces, Brother Furnace is committed to continuously improving and optimizing its products to meet the needs of different fields and provide efficient and reliable solutions.

Brother Furnace: Your Best Partner!

Vacuum graphite and carbon tube furnaces play a vital role in modern industry and scientific research due to their excellent performance and wide application prospects.

As a professional manufacturer, Brother Furnace has many technical advantages

in the design and production of vacuum graphite carbon tube furnaces. Brother

Furnace not only introduces the most advanced technology in product design but

also strictly controls the production process.

The goal of Brother Furnace is to provide customers with the most advanced and reliable products. If you have any needs or questions, please feel free to contact us.

Brother Furnace hopes that through this article, you can have a deeper understanding of the vacuum graphite carbon tube furnace.