Vacuum Aluminum Brazing Furnaces—A Cutting-Edge Solution for High-Quality Metal Joining

In today’s rapidly advancing manufacturing landscape, the demand for strong,

high-quality aluminum joints has led industries to explore more efficient

joining methods.

Vacuum aluminum brazing furnaces have emerged as revolutionary tools, providing precise, clean, and reliable solutions for joining aluminum.

This aluminum brazing technology is increasingly essential across sectors such as automotive, aerospace, electronics, and HVAC, where the quality of joints directly impacts product performance and safety.

As manufacturers strive for improvements in productivity and sustainability, high-quality aluminum joining solutions like vacuum brazing are becoming central to modern production lines.

The technology behind vacuum aluminum brazing furnaces has evolved significantly, incorporating automated systems, advanced temperature controls, and high-performance vacuum pumps that make the process more efficient and environmentally friendly.

As one of the leading vacuum furnace suppliers, Brother Furnace specializes in vacuum aluminum brazing technology, offering tailored solutions that enhance the manufacturing quality and longevity of aluminum components.

This article explores the principles, benefits, features, and applications of

vacuum aluminum brazing furnaces and why they are a preferred solution for

high-precision aluminum joining.

Understanding Vacuum Aluminum Brazing Furnaces

Vacuum aluminum brazing furnaces work on the principle of heating aluminum parts to a precise temperature in a controlled vacuum environment. This vacuum setting is critical as it eliminates oxygen, preventing oxidation and ensuring clean, smooth joints.

Unlike traditional brazing methods, which may allow contaminants to affect the joint quality, vacuum brazing processes create strong bonds without needing flux, thus reducing impurities.

The core components of a vacuum aluminum brazing furnace include:

● Temperature Control Systems: Advanced controls enable precise temperature regulation, ensuring uniform heat distribution across the brazed parts for consistent results.

● Automated Process Monitoring: Real-time monitoring and control systems allow you to minimize human error, maximize efficiency, and ensure product quality.

● Customizable Chamber Sizes and Configurations: Adaptable chambers from Brother Furnace enable flexibility, allowing furnaces to handle various aluminum parts of different sizes and shapes.

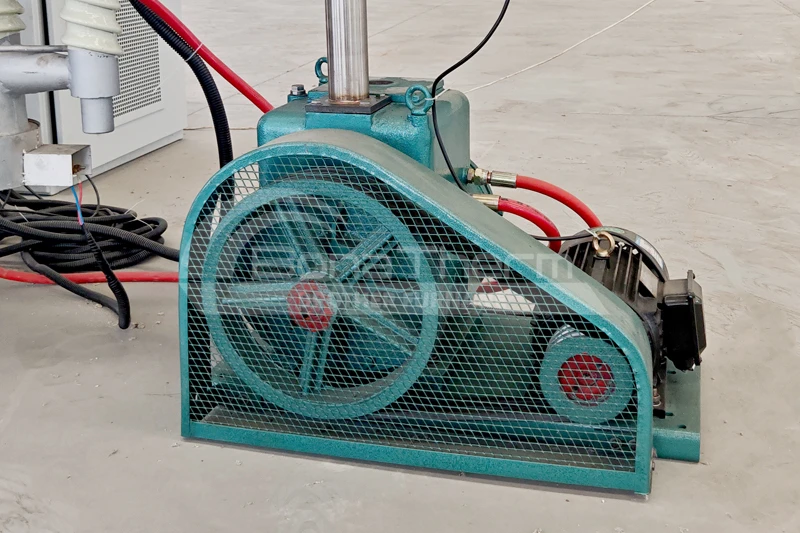

● High-Performance Vacuum Pumps: These pumps maintain the necessary vacuum conditions, which are critical for oxidation-free joints.

These features combine to create efficient brazing systems that can accommodate both high-volume production and specialized, lower-volume applications.

By maintaining strict control over environmental conditions, vacuum aluminum brazing furnaces achieve results that surpass the capabilities of traditional methods.

Benefits of Vacuum Aluminum Brazing Furnaces

Vacuum aluminum brazing furnaces deliver a range of benefits that make them highly desirable for manufacturers aiming for superior product quality and operational efficiency:

1. Superior Joint Quality and Strength: The vacuum environment ensures that aluminum joints are free of contaminants and oxidation, resulting in high-quality, durable bonds. This is particularly critical for industries like aerospace and automotive, where joint integrity affects safety and performance.

2. Enhanced Cleanliness: By eliminating the need for flux, the vacuum brazing process significantly reduces post-brazing cleaning requirements. This is not only time-saving but also results in a cleaner production environment, reducing the risk of product contamination.

3. Increased Efficiency and Productivity: Automated brazing equipment for

aluminum speeds up the production process, reduces errors, and allows for

continuous operation, maximizing output and minimizing downtime.

4. Environmental Benefits: Vacuum aluminum brazing furnaces produce fewer pollutants compared to traditional methods, making them a more sustainable choice for companies committed to reducing their environmental impact.

By providing these advanced features, Brother Furnace enables manufacturers to streamline operations, reduce costs, and improve product quality, making vacuum aluminum brazing furnaces a worthwhile investment.

Applications Across Industries

Vacuum aluminum brazing furnaces have proven to be versatile across various industries, providing efficient and high-quality solutions for aluminum joining in a wide array of applications:

● Automotive Sector: For components such as heat exchangers and radiators, vacuum furnaces for aluminum offer a durable, clean joining solution that meets the stringent demands of automotive manufacturers.

● Aerospace Industry: In aerospace, the lightweight strength of aluminum makes it a preferred material. Vacuum aluminum brazing technology ensures that structural components meet the high safety and performance standards required in this industry.

● Electronics Manufacturing: The precision and cleanliness of vacuum aluminum

brazing are invaluable for sensitive electronics like heat sinks and circuit

boards, where reliable connections are essential.

● Other Industrial Applications: In addition to these sectors, custom brazing solutions are widely applied in power generation, chemical processing, and other heavy industries where strong, oxidation-free joints are essential.

The diverse applicability of vacuum aluminum brazing furnaces makes them an asset for any industry where reliable, high-quality aluminum joints are critical.

Choosing the Right Vacuum Aluminum Brazing Furnace

When selecting a vacuum aluminum brazing furnace, it’s essential to consider factors that impact both performance and cost-effectiveness:

● Production Volume and Part Size: Large-scale operations require high-capacity industrial brazing furnaces that can handle continuous production, while smaller setups benefit from flexible, smaller-capacity furnaces.

● Budget and ROI: An initial investment in a vacuum aluminum brazing furnace offers returns in the form of long-term cost savings through reduced material and energy waste. Evaluating ROI based on production needs is a crucial step.

● After-Sales Support and Maintenance: Partnering with experienced brazing

furnace manufacturers like Brother Furnace ensures reliable after-sales support,

maintenance, and access to replacement parts, extending the furnace’s lifespan

and performance.

Future Trends in Vacuum Aluminum Brazing Technology

As technology continues to evolve, vacuum aluminum brazing furnaces are expected to incorporate features that further improve productivity, efficiency, and environmental impact:

● Advancements in Energy Efficiency: Future vacuum brazing technology developments are likely to focus on reducing energy consumption without compromising performance, meeting both environmental and economic goals.

● Potential for New Alloy Development: With ongoing research into new aluminum alloys, vacuum aluminum brazing furnaces may become increasingly adaptable to a wider range of materials, opening new possibilities for manufacturing.

These trends position Brother Furnace at the forefront of vacuum furnace technology, providing clients with future-ready vacuum aluminum brazing furnaces that meet emerging industry demands.

Conclusion

In conclusion, vacuum aluminum brazing furnaces represent a breakthrough in joining aluminum with precision and durability. The benefits, including superior joint quality, efficiency, and environmental friendliness, make them invaluable in industries requiring high-quality aluminum joints.

For businesses looking to improve their manufacturing processes, vacuum aluminum brazing technology offers unparalleled advantages.

Brother Furnace offers a comprehensive selection of vacuum aluminum brazing

furnaces tailored to meet a variety of industrial needs.

Our industrial brazing furnaces come equipped with advanced features, customizable configurations, and energy-efficient designs, ensuring that our clients receive equipment that aligns with their production goals.

If you’re exploring the potential of vacuum aluminum brazing furnaces for your business, welcome to contact Brother Furnace for expert guidance, consultation, and world-class aluminum brazing technology solutions.