Just 5 Minutes to Help You Quickly Understand Tungsten Vacuum Furnaces

In modern scientific research and high-tech manufacturing, tungsten vacuum furnaces, with their excellent high-temperature processing capability and

high-purity environmental control, have become the key equipment for many

advanced applications.

As a company specializing in manufacturing tungsten vacuum furnaces, Brother Furnace is committed to providing customers with the highest quality products through innovative design and superior manufacturing processes.

In this article, we will comprehensively introduce the definition, working

principle, main features, and application areas of tungsten vacuum furnaces,

etc., which will help you to have a deep understanding of tungsten vacuum furnaces and make a wise purchasing decision in a short time.

Tungsten Vacuum Furnace: A Comprehensive Overview

What is A Tungsten Vacuum Furnace?

The tungsten vacuum furnace is a kind of special equipment for high-temperature heating under a high vacuum environment. It is able to work stably at extreme temperatures of up to 2400°C, mainly by using tungsten mesh or tungsten wire as the heating element.

The core advantage of the vacuum tungsten furnace is its ability to perform precise heating in a high vacuum environment. This design can effectively prevent the material from reacting with oxygen or other gases during the heating process, to maintain the purity and stability of the material.

Currently, tungsten vacuum furnaces are widely used in a variety of fields, including the sintering of high-purity ceramics and the treatment of materials such as sapphire glass and zirconia.

These materials are commonly used in the manufacture of electronic equipment, optical components, and other high-tech products, which require extremely high purity and performance stability to be maintained during the production process.

Principle of Operation

The operating principle of a tungsten vacuum furnace involves 2 key

systems: the heating system and the vacuum system.

Heating System

The heating system of a vacuum tungsten sintering furnace consists mainly of tungsten mesh or tungsten wire. The extremely high melting point of these tungsten materials (approx. 3,380°C) enables them to operate stably at extreme temperatures.

The heating elements are precisely arranged in the furnace chamber and are heated by an electric current to generate high temperatures. Due to its excellent thermal conductivity and high-temperature stability, tungsten uniformly transfers heat to the material inside the furnace, thus ensuring a homogeneous and stable heating process.

Vacuum System

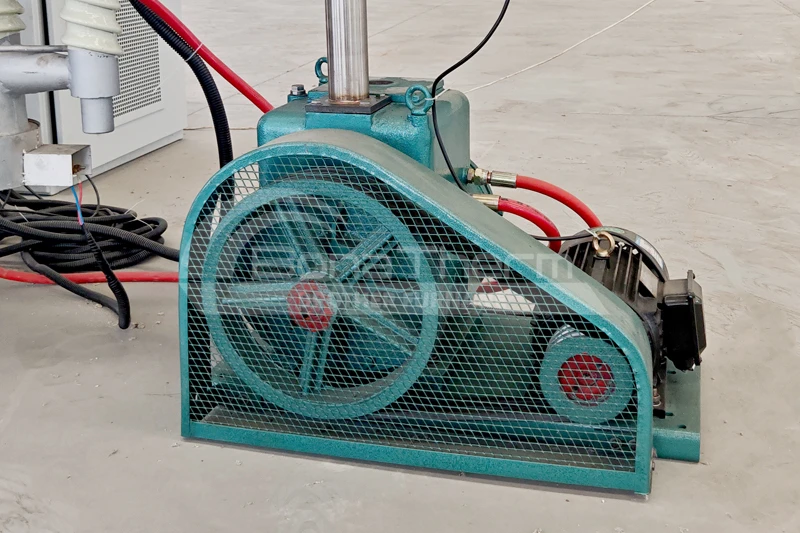

In order to ensure the purity of the material during the heating process, Brother Furnace has equipped the tungsten vacuum furnace with an advanced vacuum pump system. Directly connected vacuum pumps and molecular pumps are able to reduce the pressure inside the furnace to an ultimate vacuum level of 6x10^-4 Pa.

This high vacuum effectively prevents the influence of gases inside the

furnace on the material, thus avoiding oxidation or contamination of the

material during high-temperature treatment. The efficient performance of the

vacuum system gives the tungsten vacuum furnace a clear advantage in processing

high-purity materials.

Main Characteristics of Tungsten Vacuum Furnace

High-Temperature Performance and Stability

High-temperature vacuum tungsten furnaces are capable of supporting temperatures up to 2400°C, a level of high temperatures unattainable by many other heating devices. This high-temperature performance makes tungsten vacuum furnaces particularly good at handling high melting point materials and conducting high-temperature experiments.

Whether you are sintering high-purity ceramics or working with high-temperature materials, tungsten vacuum furnaces provide a stable and reliable heating environment.

Excellent Thermal Stability

Tungsten as a heating element has excellent high-temperature resistance and thermal stability. Under high-temperature environment, tungsten mesh can maintain stable resistance and ensure the uniformity of the heating process. Compared with other materials, tungsten is more stable at high temperatures, so tungsten vacuum furnaces are able to maintain consistent heating effects under extreme conditions.

Precise Vacuum Control

Brother Furnace's vacuum tungsten sintering furnaces are equipped with highly efficient vacuum systems, including direct-connected vacuum pumps and molecular pumps. These systems extract air from the furnace quickly and efficiently, achieving extremely low vacuum levels and ensuring material purity during the heating process.

Advanced vacuum control technology also allows customers to adjust the gas environment inside the furnace according to experimental requirements, including nitrogen, argon, hydrogen, and nitrogen-hydrogen gas mixtures.

Intelligent Control System

In order to improve the convenience and accuracy of operation, the tungsten

vacuum furnace is equipped with a high-definition touch screen and PLC automatic

control system. The touch screen provides an intuitive user interface with a

built-in operating system developed by Brother Furnace, making operation and

setup simple and intuitive.

The PLC automatic control system enables high-precision temperature and pressure control, ensuring that each step in the experimental process is executed precisely.

Application Areas of Tungsten Vacuum Furnaces

Sintering of High-Purity Ceramics

In the manufacture of high-purity ceramics, tungsten vacuum furnaces provide a stable high-temperature environment to ensure uniform sintering of ceramics. Since ceramic materials are very sensitive to temperature changes, high-temperature stability and control of the vacuum environment are critical to the quality of the final product. The high-temperature performance and precision control of high-temperature vacuum tungsten furnaces make them ideal for ceramic sintering.

Treatment of Sapphire Glass

Sapphire glass, as a material with high hardness and transparency, is widely used in optical and electronic devices. Tungsten vacuum furnaces are capable of precisely treating sapphire glass at high temperatures to ensure that its optical properties and mechanical strength meet the desired standards.

During the treatment process, the vacuum environment effectively prevents oxidation and contamination of the material, ensuring the purity of the final product.

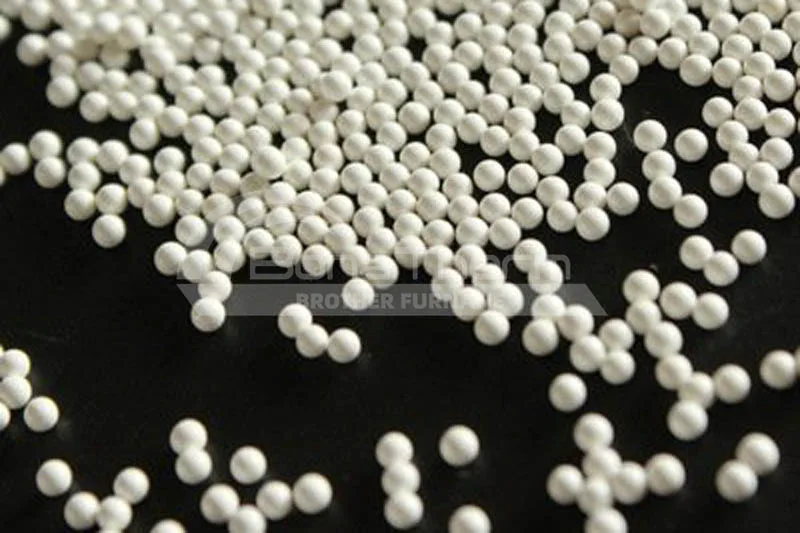

Sintering of Zirconia

Zirconia is a material with excellent mechanical properties and high

temperature resistance and is commonly used in the manufacture of high-strength

ceramics and refractory materials. Vacuum tungsten sintering furnaces can

provide a stable high-temperature environment and high vacuum to ensure the

uniformity and stability of zirconia during the sintering process. This is

essential for improving the material's performance and extending its service

life.

Handling of High-Tech Electronic Materials

In the manufacture of high-tech electronic materials, the high-temperature performance and precision vacuum control of tungsten vacuum furnaces are able to meet the stringent requirements for material purity and performance. Whether it is the treatment of semiconductor materials or the production of other electronic components, tungsten vacuum furnaces can provide a reliable high-temperature environment and stable operating conditions.

Brother Furnace: A Professional Manufacturer of Tungsten Vacuum Furnaces

With its excellent high-temperature performance, precise vacuum control, and intelligent operating system, the tungsten vacuum furnace is the ideal choice for high-purity material processing. Whether it is the sintering of high-purity ceramics, the treatment of sapphire glass, or the manufacturing of high-tech electronic materials, tungsten vacuum furnaces provide a stable and reliable heating environment.

As a professional manufacturer, Brother Furnace's tungsten vacuum furnaces

excel in both technology and performance, making them an excellent choice for

your material heat treatment.

Brother Furnace cordially invites you to contact us for more detailed information and customized solutions for tungsten vacuum furnaces.

The team at Brother Furnace will be happy to provide you with the highest quality products and services to help you succeed in your research and production endeavors.