Professional Brazing Equipment: Vacuum Brazing Furnace

As a professional brazing equipment, vacuum brazing furnace has won wide

recognition in many industries for its unique advantages.

In the modern manufacturing industry, the brazing process is widely used in electronics, aerospace, and medical devices, etc., which has become a key technology for connecting different materials and enhancing product performance.

As a company specializing in the manufacture of vacuum brazing furnaces, Brother Furnace is committed to providing efficient and reliable equipment to help customers stand out from the competition.

This article will provide an in-depth introduction to the principles,

advantages and applications of vacuum brazing furnaces, hoping to help you

understand the specialized equipment for brazing.

The Working Principle of Vacuum Brazing Furnace

A vacuum brazing furnace realizes the connection between materials by heating metal parts in a vacuum environment to reach the temperature required for brazing.

Establishing a vacuum environment: The air is extracted in the furnace chamber and the pressure is lowered to prevent oxidation and other chemical reactions. The level of vacuum directly affects the quality of brazing, and the ultimate vacuum of Brother Furnace's vacuum brazing furnace can reach 7x10-3pa.

Heating: The brazing furnace uses highly efficient heating elements to quickly and uniformly raise the temperature inside the furnace to the level required for brazing. The control of the heating rate and temperature is critical in this process to ensure that the brazing material flows evenly and penetrates fully.

Material bonding: Under high temperatures and a vacuum environment, the brazing material melts and flows into the gap between the parts being joined, forming a strong bond.

Cooling: At the end of the heating process, the temperature in the furnace is gradually lowered and the brazed joint cools to ensure bond strength and stability. The control of cooling speed also has an important effect on the welding effect, too fast cooling may lead to material stress concentration.

Advantages of Vacuum Brazing Furnaces

1. Superior Brazing Quality

Vacuum brazing furnaces can weld in an oxygen-free environment, which greatly

reduces the oxidation and nitriding of the material during the welding process

and ensures the purity and strength of the welded joint. This high quality of

welded joints is especially important in demanding application scenarios, such

as the aerospace and medical device industries.

2. Increased Productivity

Compared with traditional soldering methods, vacuum brazing furnaces allow for rapid heating and uniform cooling, thus shortening production cycles. The efficient heating system enables the equipment to reach the required working temperature in a short period, improving overall productivity.

3. Flexible Process Adaptability

The vacuum brazing furnace is suitable for the welding of a variety of materials, including aluminum, copper, stainless steel, and other metals, as well as a variety of brazing materials. Its flexibility allows the equipment to be adjusted to different production requirements and adapt to different welding tasks.

4. Reduced Production Costs

Although the initial investment is relatively high, the vacuum brazing furnace can effectively reduce production costs in long-term use. By reducing material waste, improving soldering efficiency, and reducing the defective rate, the overall economic benefits of the equipment are significant.

The Main Components of Vacuum Brazing Furnace

Vacuum brazing furnace has a complex design, mainly composed of the following parts:

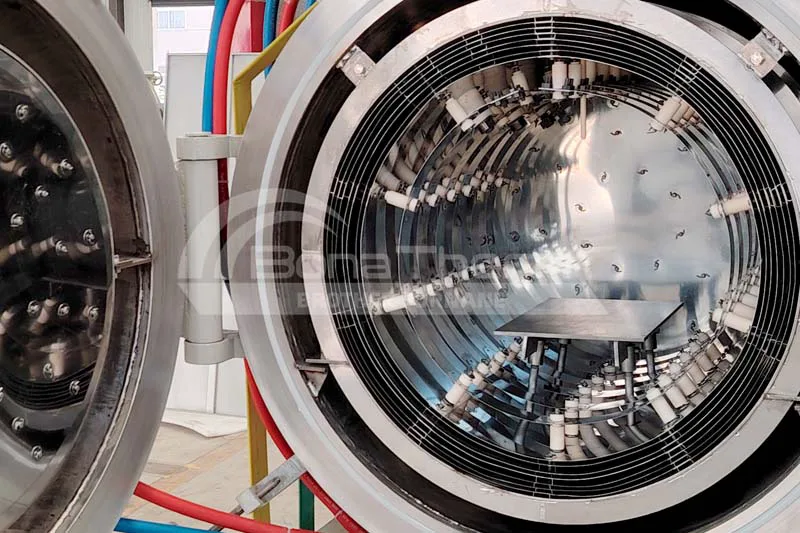

1. Furnace Chamber

The furnace chamber is the core part of the vacuum brazing furnace, which is

made of high-strength heat-resistant materials (e.g. molybdenum foil metal,

stainless steel metal) to withstand the double test of high temperature and

vacuum environment.

2. Vacuum System

The vacuum system is responsible for extracting air from the furnace to ensure that the brazing process takes place in a vacuum environment. The system usually consists of a vacuum pump, vacuum valves, and pressure sensors to monitor and regulate the furnace pressure in real time.

3. Heating System

The heating system is a key component of the welding process and usually consists of a resistance heater and a temperature controller. It ensures the stability of the welding process by precisely controlling the heating speed and temperature.

4. Control System

Modern vacuum brazing furnaces are equipped with advanced automated control systems, which can be programmed to set the parameters of the heating, cooling, and vacuum processes to achieve fully automated operation. The operator only needs to monitor the whole process to ensure that the equipment runs normally.

Application Areas of Vacuum Brazing Furnace

Vacuum brazing furnace has been widely used in many industries, mainly including:

1. Electronics industry

In the manufacture of electronic products, professional brazing equipment is

used to connect circuit boards and other electronic components to ensure the

stability and reliability of the connection. This is critical to the performance

of products such as cell phones and computers.

2. Aerospace

The aerospace industry requires high strength and reliability of material connections, and vacuum brazing furnaces can provide ideal welding solutions, widely used in the manufacture of aircraft, satellites, and other complex structures.

3. Medical devices

The medical device industry requires non-polluting, high-strength welded joints, vacuum brazing furnaces with their unique welding quality have become the preferred equipment for medical device manufacturing. Especially in the production of cardiac stents and other key components, its importance is self-evident.

4. Automobile Manufacturing

In automobile manufacturing, a vacuum brazing furnace can be used to connect engine parts and other key structures to improve the safety and durability of the whole vehicle.

How to Choose a Vacuum Brazing Furnace

When choosing a vacuum brazing furnace, there are 4 factors to consider:

1. Vacuum Level of the Equipment

Different applications require different vacuum levels, and choosing the

right vacuum level can ensure soldering quality. For example, the aerospace and

medical industries usually require higher vacuum levels.

2. Heating Method

Brother Furnace's vacuum brazing furnaces can be heated in a variety of ways, such as by electric alloy tubes and molybdenum heating tapes. Choosing the right heating method can improve the welding efficiency and quality.

3. Intelligent degree of control system

At present, professional brazing equipment increasingly relies on automation and intelligence. Choosing a vacuum brazing furnace equipped with an advanced control system can realize more efficient production management.

4. Manufacturer's Technical Support

By choosing a reputable supplier of vacuum brazing furnaces, you can get better after-sales service and technical support to ensure that the brazing furnace is kept in the best condition during use.

Advantages of Brother Furnace

As a manufacturer of vacuum brazing furnaces, Brother Furnace has many years

of industry experience and technology accumulation.

High efficiency: Brother Furnace's vacuum brazing furnaces use advanced heating technology to ensure rapid warming and even heating, improving productivity.

Stability: Each brazing furnace is strictly tested before it is sold to customers. This ensures that the equipment can operate stably in various environments.

Professional service: Brother Furnace provides you with comprehensive technical support and after-sales service to ensure that customers have no worries about the use of the process.

Vacuum Brazing Furnace: Creating High-Quality Welding Solutions

Vacuum brazing furnace plays a vital role in the modern manufacturing industry, and their excellent welding quality, productivity, and flexibility make them the preferred equipment in various industries. As a professional brazing furnace manufacturer, Brother Furnace understands the importance of equipment quality and technical support to customers.

Therefore, Brother Furnace is always committed to providing efficient and professional brazing equipment to help you achieve your production goals and reduce operating costs.

Brother Furnace is looking forward to cooperating with you to create a bright future together! Feel free to contact us anytime.