Molybdenum Vacuum Furnaces: Revolutionizing High-Temperature Processing

Industrial processes that demand high temperatures, precision, and material

purity always require cutting-edge solutions. Among these solutions, the

molybdenum vacuum furnace has emerged as a leading technology.

With its ability to maintain ultra-high temperatures and a controlled vacuum environment, it has become an indispensable tool in industries such as aerospace, semiconductor manufacturing, and advanced material production.

In this article, Brother Furnace will explore what makes these furnaces unique, their key benefits, and why they are critical for modern industrial applications.

We will also provide practical guidance for choosing the right furnace, ensuring you can maximize efficiency and output while reducing costs.

Understanding Molybdenum Vacuum Furnaces

What is a Molybdenum Vacuum Furnace?

A molybdenum vacuum furnace is a type of high-temperature furnace that uses molybdenum heating elements within a vacuum chamber to process materials. Molybdenum, with its high melting point and exceptional thermal stability, is an ideal material for furnaces operating in extreme conditions.

These furnaces are designed for processes requiring precise temperature control and contaminant-free environments, ensuring superior results.

How Does a Molybdenum Vacuum Furnace Work?

The operation of a molybdenum vacuum furnace relies on three critical components:

Vacuum System: Removes oxygen and other gases from the chamber, creating an inert or vacuum environment. This prevents oxidation and contamination during processing.

Heating Elements: Molybdenum heating elements generate and maintain high temperatures efficiently.

Control Systems: Advanced automation and monitoring systems precisely control temperature and vacuum levels, ensuring consistent results.

This combination allows these furnaces to perform complex processes such as vacuum heat treatment, vacuum brazing, and vacuum sintering with unmatched precision.

Comparison with Traditional Furnaces

Traditional furnaces operate in open-air environments and are often limited in their temperature range. By contrast, molybdenum vacuum furnaces offer:

● Higher temperature capabilities.

● Contaminant-free processing environments.

● Greater energy efficiency. These differences make industrial vacuum furnaces the preferred choice for industries requiring advanced thermal processing.

Advantages of Molybdenum Vacuum Furnaces

High-Temperature Capabilities

Molybdenum vacuum furnaces can reach temperatures exceeding 1300°C, making

them ideal for processing refractory metals and materials that require extreme

heat for brazing, annealing, or melting.

Exceptional Purity in Processing

By operating in a vacuum, these furnaces eliminate the risk of oxidation and contamination, ensuring the highest level of material purity. This is critical for industries like semiconductor manufacturing and medical device production, where impurities can compromise product performance.

Energy Efficiency

As an energy-efficient furnace, using molybdenum heating elements minimizes energy loss, reducing operational costs. This efficiency is especially important for businesses looking to improve sustainability and reduce their carbon footprint.

Precise Temperature Control

Advanced control systems allow operators to fine-tune temperature settings with incredible accuracy, ensuring optimal conditions for processes like vacuum sintering and vacuum brazing.

Uniform Heating

Heat distribution in a molybdenum vacuum furnace is remarkably uniform,

reducing the risk of defects or inconsistencies in processed materials. This

uniformity is crucial for applications such as metal processing and advanced

material furnace operations.

Durability and Longevity

Thanks to the resilience of molybdenum furnace parts, these furnaces have a long operational lifespan, reducing downtime and maintenance costs. This durability ensures a high return on investment over time.

Key Applications of Molybdenum Vacuum Furnaces

Aerospace Industry

In aerospace, the precision and reliability of vacuum heat treatment are essential for manufacturing turbine blades, structural components, and other critical parts. Molybdenum vacuum furnaces deliver the high temperatures and contaminant-free conditions needed for these demanding applications.

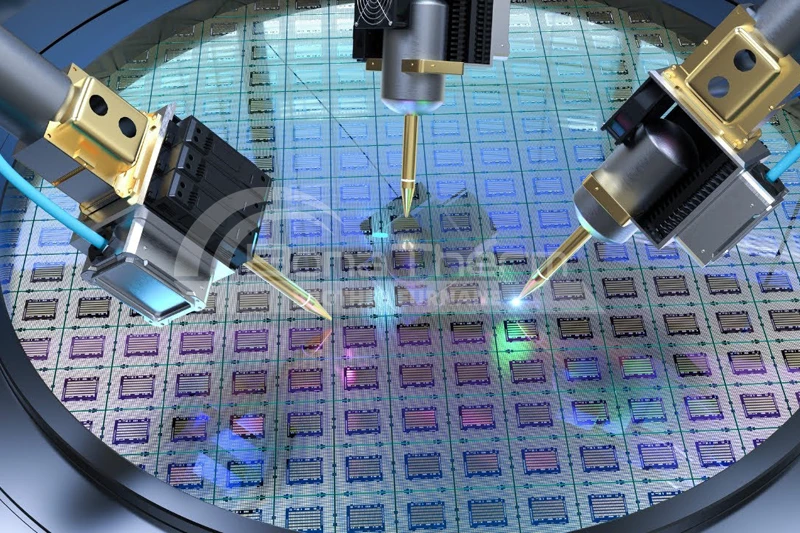

Semiconductor Manufacturing

The production of semiconductors requires ultra-clean environments and

precise thermal control to ensure the integrity of chips and microelectronics.

Vacuum sintering furnaces are indispensable for achieving these standards,

making them a vital component of the electronics industry.

Medical Device Production

From surgical instruments to implantable devices, the medical industry depends on materials that meet stringent purity and durability requirements. Molybdenum thermal processing ensures these products are free from contaminants and built to last.

Research and Development

Researchers working on advanced materials rely on custom vacuum furnaces to explore new processes like sintering, brazing, and annealing. The adaptability and precision of these furnaces make them ideal for experimental applications.

Advanced Materials Processing

Industries producing high-performance alloys, composites, and other advanced materials rely on high-performance furnaces to achieve consistent results. The ability to process materials under controlled conditions makes molybdenum vacuum furnaces an invaluable tool.

Technical Specifications

Temperature Range

Molybdenum vacuum furnaces can achieve temperatures exceeding 1300°C, making them suitable for the most demanding thermal processes.

Size and Capacity Options

From compact models designed for R&D to large-scale production units,

Brother Furace’s custom vacuum furnaces are available in various sizes to meet

diverse needs.

Automation and Control Systems

Modern molybdenum vacuum furnaces feature advanced automation, real-time monitoring, and precise control systems to enhance productivity and reliability.

Choosing the Right Molybdenum Vacuum Furnace

Assess Your Needs

Consider the specific requirements of your application, whether it’s vacuum brazing, vacuum sintering, or another process. Identify the temperature, capacity, and purity levels you require.

Customization Options

Leading manufacturers like Brother Furnace offer tailored solutions to meet industry-specific needs. Customization options include enhanced molybdenum furnace parts, specialized control systems, and size adjustments.

Maintenance and Support

Ensure the furnace comes with comprehensive maintenance support and

easy-to-replace components. Regular servicing can significantly extend the

lifespan of your equipment.

Return on Investment

Long-Term Cost Savings

While the initial investment in a molybdenum vacuum furnace may be higher, its energy efficiency and durability result in significant cost savings over its lifespan.

Improved Product Quality

The precision and purity achieved with these furnaces enhance product quality, reducing defects and waste.

Enhanced Productivity

The advanced automation and reliability of high-performance furnaces allow for faster processing cycles, increasing throughput and profitability.

Environmental Benefits

As an energy-efficient furnace, the reduced energy consumption of a molybdenum vacuum furnace helps companies meet sustainability goals.

Conclusion

The molybdenum vacuum furnace has transformed high-temperature industrial processes with its unique capabilities. From aerospace and semiconductors to advanced materials and medical devices, its applications are vast and varied. Offering precision, energy efficiency, and unparalleled purity, these furnaces are a critical investment for industries looking to enhance their capabilities and stay competitive.

For businesses seeking cutting-edge solutions, Brother Furnace is a trusted

provider of state-of-the-art molybdenum vacuum furnaces.

With customizable options and comprehensive support, we ensure our furnaces meet the specific needs of your operations. Contact us to explore how our solutions can help you achieve excellence in high-temperature processing.

By investing in a molybdenum vacuum furnace, you’re not just improving your processes—you’re paving the way for greater productivity, quality, and sustainability. Let Brother Furnace be your partner in this journey toward industrial innovation.