Metal Vacuum Hardening Furnaces -- Creating Excellent Properties for Metals

- By: Brother Furnace

- 2024-12-31 01:30

Brother Furnace's vacuum hardening furnace for metal parts is an outstanding

representative of modern heat treatment technology. It integrates advanced

vacuum technology, a precise temperature control system, and an efficient

cooling mechanism and is designed to meet the heat treatment needs of

high-performance metal materials.

The vacuum hardening furnace for metal parts not only complies with

international heat treatment standards, but also shows excellent performance and

wide application prospects in many fields, and is an indispensable tool for

aerospace, automobile manufacturing, precision machinery, tool manufacturing,

and other industries to improve product quality and extend service life.

Multi-discipline, High-precision Metal heat Treatment Solutions

Aerospace: A metal vacuum quenching furnace can provide precise heat treatment for aircraft engine blades, turbine disks, and other critical components to ensure their stability and durability under extreme conditions.

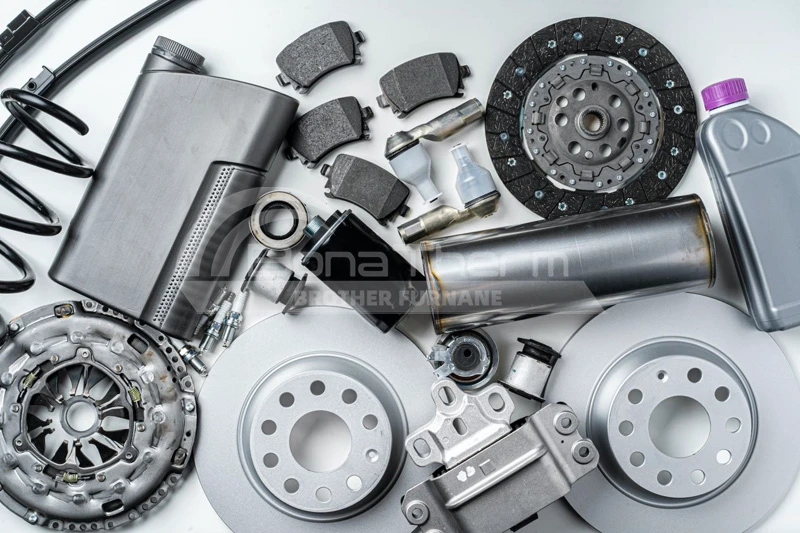

Automotive Manufacturing: Optimize the mechanical properties of automotive parts such as gears, shafts, bearings, etc., to improve wear resistance and service life, to meet the trend of automotive lightweight and high performance.

Precision Machinery: After heat treatment, ensure the dimensional stability and accuracy of precision molds, cutting tools, gauges, etc., providing a reliable guarantee for precision manufacturing.

Tool Manufacturing: Enhance the hardness and abrasion resistance of cutting

tools, stamping dies and other tools, prolong service life, and reduce

replacement frequency.

Why Choose Metal Vacuum Hardening Furnace for Metal Processing

1. Extremely Low Oxidation and Decarburization Rate

Heat treatment of metal in a vacuum environment, so that the chance of metal workpiece contact with oxygen is almost zero, thus effectively avoiding the phenomenon of oxidation and decarburization, ensuring the integrity of the original composition and properties of the metal material.

2. Perfect Surface Quality

The vacuum quenching process significantly reduces the formation of oxidized skin, and the surface of the workpiece is smoother and flatter without additional grinding and polishing treatment, which reduces the production cost and improves production efficiency.

3. Environmental Protection and Energy Saving

Brother Furnace has given full consideration to environmental protection and energy-saving requirements in the design and manufacture of metal vacuum hardening furnaces.

Throughout the heat treatment process, the vacuum hardening furnace for metal parts does not produce pollutants such as smoke, dust, or exhaust gases, which is in line with the requirements of modern industry for environmental protection and sustainable development.

4. Wide Applicability

Metal vacuum quenching furnaces are suitable for various types and sizes of metal workpieces, whether small precision parts or large heavy-duty parts, and can get uniform and stable heat treatment effects, to meet the diversified needs of customers.

What Helps Metal Processing with Metal Vacuum Hardening Furnace

Highly Efficient Heating System:

It consists of a graphite heating body, graphite soft felt, and hard felt to form the heating chamber, and the maximum operating temperature is up to 1350℃.

Multiple columns of graphite nozzles are evenly distributed in the wall of the heating chamber to ensure that the gas is uniformly ejected to achieve uniform quenching.

Advanced Gas Cooling System:

The vacuum hardening furnace for metal parts is equipped with a high-pressure impeller fan, a multi-stage high-efficiency copper heat exchanger, and a duct deflector to realize rapid and uniform gas cooling.

The gas cooling pressure of 1-10 bar can be adjusted at will to meet different process requirements.

Maximum cooling rate: the empty furnace cools from 1150℃ to 250℃ in less than 7 minutes (cooling water temperature is less than 35℃). High-quality Heating Elements:

You can choose graphite or molybdenum foil etc. as the heating element. No volatilization, no impurity, and no pollution to the heat treatment workpiece.

Unique Material Table Design:

The charging table consists of graphite pillars, graphite hearth, and Al₂O₃ spacer strips on the hearth, which prevents the bonding of the charging disk and graphite hearth at high temperatures.

Comprehensive Auxiliary Systems:

Vacuum systems, electric control systems, filling systems, water-cooling systems, pneumatic systems, and transportation vehicles outside the furnace are all available to ensure the stable operation of the equipment.

Brother Furnace: Provide the Most Professional and Comprehensive Support for You

Brother Furnace's vacuum hardening furnace for metal parts specializes in the ultimate enhancement of metal properties. With our metal vacuum hardening furnaces and professional services, your metals will exhibit higher hardness, strength, wear resistance, and corrosion resistance, significantly increasing the service life and performance of your products.

Brother Furnace also offers personalized customization services, both in terms of chamber size and heating temperature, to precisely match your production needs and ensure the best metal treatment results.

At the same time, our technical support, operation training, and after-sales service team will accompany you throughout the whole process to ensure that your production process is smooth and unimpeded.

When you choose Brother Furnace, you are choosing a professional partner in the field of metal treatment. We look forward to working with you to promote the innovation and development of metal heat treatment technology.