Induction Melting Furnace Manufacturer: Brother Furnace

Induction melting furnaces are essential in the modern manufacturing

industry, providing an efficient and reliable method of melting metals for

various applications.

These furnaces utilize electromagnetic induction to heat and melt metals, offering advantages such as precise temperature control, energy efficiency, and minimal oxidation of materials.

As a leading manufacturer in this field, Brother Furnace has established a strong reputation for producing high-quality induction melting furnaces designed to meet the needs of diverse industries, from steel production to foundry operations.

The Role of Induction Melting Furnaces in Modern Industry

Induction melting furnaces have become a cornerstone in industrial

applications, particularly for melting metals efficiently and cost-effectively.

Unlike traditional furnaces that rely on fuel combustion, induction melting

furnaces use electric currents to generate heat through electromagnetic

induction, which is both clean and highly efficient.

This method provides several key benefits over conventional heating techniques.

Firstly, induction furnaces allow for more precise temperature control, making them ideal for industries that require strict adherence to thermal conditions, such as precision casting or alloy production.

Secondly, they reduce the risk of contamination during the melting process, as there is no direct contact between the metal and the heat source. This is particularly important in industries like aerospace, automotive, and electronics, where the purity of the metal is critical to the final product’s performance and durability.

Brother Furnace: A Leading Manufacturer of Induction Melting Furnaces

Brother Furnace, a trusted name in the field of heat treatment equipment, is renowned for its cutting-edge induction melting furnaces. The company has built a reputation for quality, innovation, and reliability in the furnace manufacturing sector.

With years of experience in designing and producing industrial furnaces, Brother Furnace has developed a comprehensive range of induction melting furnaces that cater to various industries and applications.

One of the key factors that set Brother Furnace apart from its competitors is

its commitment to technological innovation. By incorporating advanced features

and the latest technologies into their furnaces, Brother Furnace ensures that

customers receive products that not only meet but exceed industry standards.

Whether a small-scale operation or a large industrial plant,Brother Furnace’s induction melting furnaces offer outstanding performance, durability, and energy efficiency.

Features of Brother Furnace’s Induction Melting Furnaces

Energy Efficiency

One of the most important considerations when choosing an induction melting furnace is energy consumption. Brother Furnace’s induction melting furnaces are designed with energy efficiency in mind.

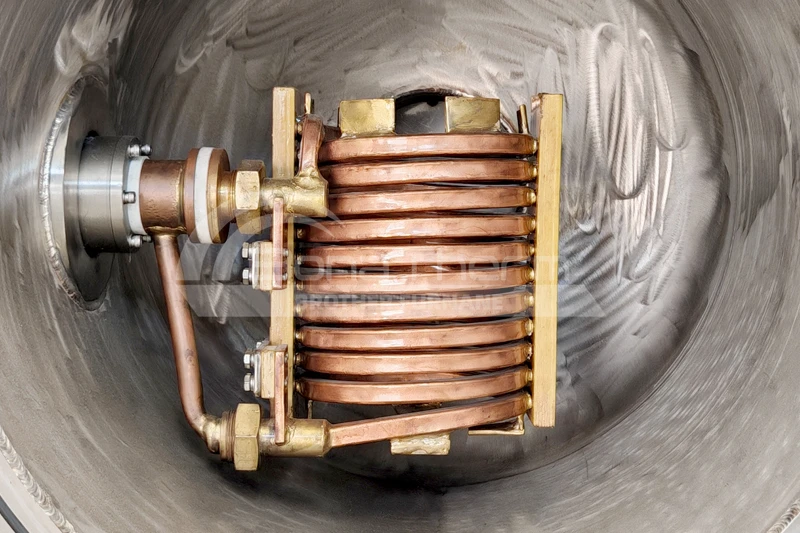

By utilizing advanced power control systems and optimizing coil design, the furnaces maximize energy usage while minimizing heat loss. This not only reduces operational costs but also makes them environmentally friendly, helping companies reduce their carbon footprint.

High Precision and Control

The precision of the induction melting process is a significant advantage. Brother Furnace’s induction melting furnaces are equipped with state-of-the-art temperature control systems that allow for accurate adjustments throughout the melting process. This ensures that the metal reaches the desired temperature without fluctuations, which is essential for maintaining quality and consistency in the final product.

Fast Melting Time

Another major advantage of induction melting furnaces is their fast melting

time. Traditional furnaces may take hours to melt large quantities of metal, but

induction melting furnaces from Brother Furnace can achieve the same results in

a fraction of the time. This increases productivity and reduces downtime, making

it an ideal solution for high-volume operations.

Minimal Oxidation

Oxidation of metals during the melting process can lead to impurities and affect the quality of the final product. Induction melting furnaces from Brother Furnace are designed to minimize oxidation, helping to preserve the purity of the molten metal.

This is especially important in industries that rely on high-quality alloys and precision materials, such as aerospace, automotive, and medical device manufacturing.

Durability and Reliability

Brother Furnace’s induction melting furnaces are built to last. Constructed with high-quality materials and engineered to withstand the harsh conditions of industrial environments, these furnaces offer exceptional durability and reliability. The robust design ensures that the furnaces can handle the rigorous demands of continuous operation, reducing maintenance costs and downtime.

Customization Options

Brother Furnace understands that each customer’s needs are unique. That’s why

they offer a variety of customization options for their induction melting

furnaces. Whether it’s specific furnace size, additional features, or special

materials for the furnace lining, Brother Furnace works closely with customers

to design and deliver a solution tailored to their exact requirements.

Safety Features

Safety is a top priority for Brother Furnace. Our induction melting furnaces come equipped with a variety of safety features to protect operators and ensure safe operation. These include temperature sensors, over-temperature protection, emergency shutoff switches, and fail-safe mechanisms that help prevent accidents and equipment damage.

Industries That Benefit from Brother Furnace’s Induction Melting Furnaces

Brother Furnace’s induction melting furnaces are used across a wide range of industries, including:

Steel and Foundry: The steel industry relies heavily on induction melting furnaces to process scrap metal and create high-quality alloys. Brother Furnace’s furnaces provide precise temperature control, energy efficiency, and minimal oxidation, making them an excellent choice for steel production and casting operations.

Automotive: In the automotive industry, the production of high-performance

parts and alloys is critical. Induction melting furnaces from Brother Furnace

are used to melt metals for components like engine parts, transmission

components, and structural components. The precision and reliability of these

furnaces help ensure that automotive manufacturers can produce parts that meet

the stringent requirements of the industry.

Aerospace: Aerospace manufacturers need to produce parts with exceptional strength, durability, and resistance to extreme temperatures. Induction melting furnaces from Brother Furnace are perfect for melting high-performance alloys used in the production of aircraft components. The ability to control the temperature accurately ensures that the properties of the materials remain consistent throughout the melting process.

Electronics: The electronics industry relies on high-purity metals for components like semiconductors and connectors. Brother Furnace’s induction melting furnaces offer a clean melting process with minimal oxidation, helping to preserve the integrity of the metal and ensure the quality of the final product.

Medical Devices: Medical device manufacturers require precision materials that meet stringent regulatory standards. Induction melting furnaces from Brother Furnace are used to melt high-quality metals for medical implants, surgical instruments, and other critical components.

Why Choose Brother Furnace for Your Induction Melting Furnace Needs?

When it comes to purchasing an induction melting furnace, there are several factors to consider: reliability, performance, energy efficiency, and cost-effectiveness. Brother Furnace stands out as a leading manufacturer due to its commitment to excellence in all of these areas. By choosing Brother Furnace, customers can benefit from:

Proven Quality: Brother Furnace has a long track record of producing

high-quality induction melting furnaces that are trusted by industries

worldwide. With a focus on durability and precision, Brother Furnace ensures

that every furnace meets or exceeds industry standards.

Custom Solutions: Brother Furnace understands that every application is different. We offer a range of customizable options to meet the specific needs of each customer. Whether you need a furnace for small-scale operations or large industrial applications, Brother Furnace can provide a tailored solution that fits your requirements.

Energy Efficiency: With rising energy costs, energy-efficient solutions are more important than ever. Brother Furnace’s induction melting furnaces are designed to maximize energy efficiency, helping customers reduce operating costs and improve profitability.

Customer Support: Brother Furnace is dedicated to providing exceptional customer support throughout the entire process, from product selection and installation to ongoing maintenance and troubleshooting. Their experienced team is always available to assist with any questions or concerns.

Conclusion

Brother Furnace is a leading manufacturer of induction melting furnaces that offers innovative, high-performance solutions for a wide range of industries.

With a focus on energy efficiency, precision, and durability, our furnaces provide reliable and cost-effective solutions for melting metals in applications that require the highest standards of quality.

By choosing Brother Furnace, customers can be confident in their investment, knowing that they are working with a trusted and experienced manufacturer committed to delivering the best products and services in the industry.

Whether you’re in steel production, aerospace, automotive, or another industry, Brother Furnace’s induction melting furnaces are the perfect choice to meet your needs.