How to Maintain Vacuum Furnaces

- By: Brother Furnace

- 2024-09-09 02:01

Vacuum furnaces play an indispensable role in industrial manufacturing, and

their performance has a direct impact on product quality and productivity. To

ensure the stable and efficient operation of a vacuum furnace, regular

maintenance is essential.

In this article, Brother Furnace will systematically introduce how to maintain a vacuum furnace, including daily inspection, regular maintenance, and in-depth maintenance.

In daily inspection, you can prevent and solve potential problems through appearance inspection, vacuum system inspection, and temperature control system inspection. Regular maintenance covers key steps such as filter cleaning and replacement and temperature control system calibration. In-depth maintenance. It is recommended that you perform internal inspections and repairs, software system updates, and create maintenance records.

As a professional vacuum furnace manufacturer, Brother Furnace hopes that through these detailed instructions, you will not only have a comprehensive understanding of vacuum furnace maintenance methods but also be able to effectively improve the operational stability of your vacuum furnace and extend its service life.

Daily Inspection of Vacuum Furnace

1. Exterior Inspection

Routine exterior inspection is the first step in maintenance. First, check the overall condition of the furnace structure and its accessories, including the furnace door, seals, locks, and connecting pipes. Make sure that there is no visible physical damage such as cracks, corrosion, or wear. The seals, in particular, as they are directly related to the vacuum level of the furnace, should be checked regularly for integrity and elasticity to prevent air leakage.

Any abnormalities found should be repaired immediately to prevent further damage to the equipment. Brother Furnace's vacuum furnaces are equipped with advanced sealing technology and wear-resistant materials, which greatly reduce the risk of air leakage and damage and provide more reliable protection for your production.

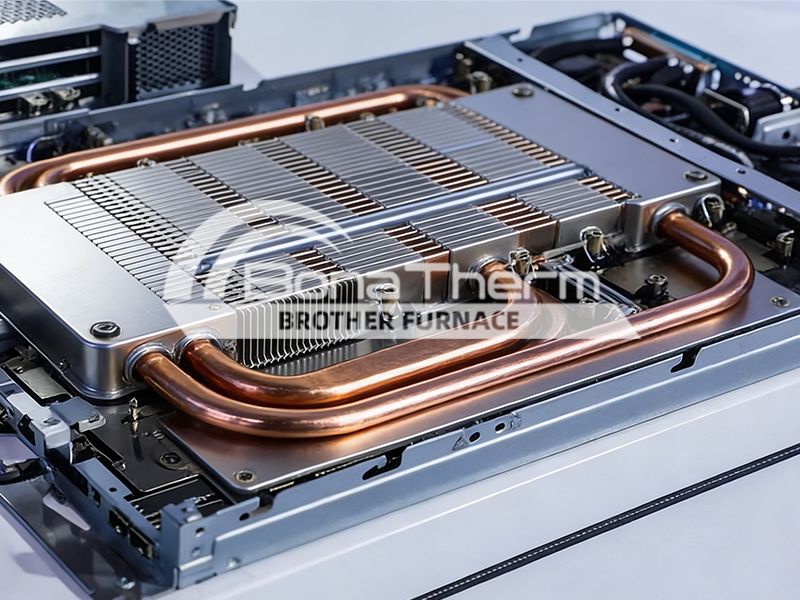

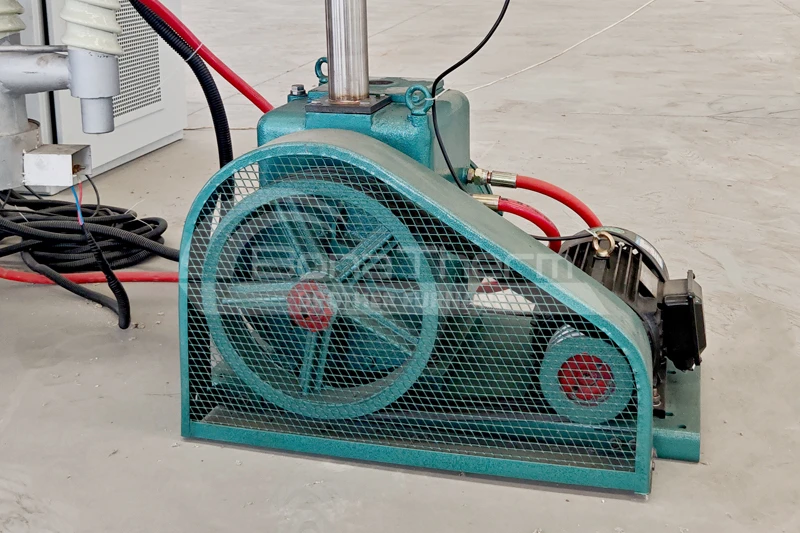

2. Inspection of the Vacuum System

The inspection of the vacuum system is crucial. The vacuum pump of the vacuum furnace is the core component to maintain the vacuum environment in the furnace. Regularly checking the oil level and quality of the vacuum pump is a basic requirement for maintenance. Low oil level, or poor oil quality may lead to a decline in the performance of the vacuum pump, affecting the vacuum in the furnace.

Vacuum valves are also the focus of inspection, which should be ensured to open and close properly to avoid vacuum leakage caused by valve failure.

If a decrease in vacuum is found, all possible leakage points, including pipe

connections and furnace seams, should be checked first.

3. Check the Temperature Control System

The accuracy of the temperature control system directly affects the heat treatment effect in the furnace. Checking the accuracy of the temperature sensors is necessary. Any deviation of the sensors will lead to unstable temperature control. It is recommended that the temperature sensors be calibrated regularly using a calibration instrument to ensure the accuracy of their output data.

It is also necessary to check other components of the temperature control system, such as heating elements and controllers, to confirm that they are working properly and are not malfunctioning or damaged. Brother Furnace's vacuum furnaces utilize advanced temperature control technology to ensure high-precision temperature control and can provide accurate temperature protection for your production process.

Regular Maintenance

1. Clean and Replace the Filter

During the operation of the vacuum furnace, airborne dust and impurities gradually accumulate on the filter. Regular cleaning of the filter prevents impurities from damaging the vacuum system and other components. The exact frequency of cleaning depends on how often your vacuum furnace is used and the environmental conditions.

When the filter is damaged, replace the filter promptly to ensure the efficiency of the filter and the normal operation of your high-temperature vacuum furnace.

2. Calibrate the Temperature Control System

Calibration of the temperature control system is an important measure to

ensure the stable performance of the vacuum furnace. After long-term use, the

temperature control system may drift, resulting in the actual temperature is not

consistent with the set temperature.

Regular calibration of the temperature control system can correct these deviations and ensure the accuracy of the temperature in the furnace, thus ensuring the precision of the heat treatment process. If you find a large temperature deviation during the later use of Brother Furnace's vacuum furnace, you can contact Brother Furnace at any time.

3. Lubrication and Maintenance

Mechanical parts of the vacuum furnace, such as the slides and locking devices of the furnace door, need to be lubricated regularly to keep them in good motion. Selecting the proper lubricant and applying it according to the manufacturer's recommendations will reduce friction and wear and prevent mechanical failure. The frequency of lubrication should be adjusted according to the usage of the components.

In-depth Maintenance

1. Internal Inspection and Repair

Wear and deterioration of internal components are inevitable after a long period of operation of the vacuum furnace. It is recommended that you stop the machine periodically for internal inspection so that potential problems can be detected and solved in time.

On the other hand, check the heating elements inside the furnace for deterioration, breakage or other damage to ensure that they are working properly. Any damaged components should be repaired or replaced immediately to prevent the overall performance of the equipment from being affected. Brother Furnace can not only provide you with professional vacuum furnaces but also provide you with excellent heating elements and so on.

2. Update of Software System

Modern vacuum furnaces are usually equipped with complex control software,

which plays an important role in the operation and function of the equipment.

Regularly checking and updating the software system provides access to the

latest features and fixes, improving the overall performance and stability of

the equipment.

The updating of software also helps to fix known vulnerabilities and improve the security of the system. Brother Furnace provides customers with comprehensive software support to ensure that your vacuum furnace is always running at an optimized state.

3. Records of Maintenance

Keeping detailed maintenance records is part of good maintenance practice. Recording what, when, and what problems are found with each maintenance program helps track equipment usage and maintenance history. These records not only help to identify trends and potential problems over time but also provide a useful reference when needed to guide future maintenance.

Why Maintenance is Recommended for Your Vacuum Furnace

Maintaining your vacuum furnace is key to ensuring the performance and

longevity of your equipment. By implementing routine inspections, regular

maintenance, and advanced care measures, you will not only increase the

efficiency of your furnace but also reduce the risk of breakdowns and ensure the

stability of your production process.

As a professional high-temperature vacuum furnace manufacturer, Brother Furnace is committed to providing high-quality vacuum furnaces and excellent after-sales service to ensure that your equipment is always in the best condition.

We hope that the detailed instructions in this article will help you better maintain your vacuum furnace and optimize its performance.

If you have any questions or need further technical support, please feel free to contact us. Brother Furnace will provide you with professional solutions and services.