How to Choose High Temperature Vacuum Furnace

In modern industry and scientific research, high-temperature vacuum furnaces

are widely used in material science, electronics manufacturing, aerospace, and

other fields because of their excellent heat treatment performance and precise

control ability.

As a professional manufacturer of high-temperature vacuum furnaces, Brother Furnace understands that choosing a suitable high-temperature vacuum furnace is crucial to the accuracy of experimental results and the improvement of production efficiency.

This guide will introduce you to the key factors to consider when purchasing a high temperature vacuum furnace to help you make an informed decision.

Basic Information about High-Temperature Vacuum Furnaces

What is a Vacuum Furnace

A high-temperature vacuum furnace is a device that performs high-temperature

processing in a high-vacuum environment. It is mainly used for sintering,

annealing, synthesizing and other processes of materials to avoid oxidation and

contamination and to ensure the purity and quality of materials.

The unique combination of its high-temperature performance and vacuum environment makes it show excellent advantages in processing special materials and high-tech products.

Main Areas of Application

Materials science: for the sintering and synthesis of new materials, such as ceramics, metal alloys, etc.. These materials often need to be treated under extreme conditions to ensure that their properties are optimized.

Electronics manufacturing: for annealing and lithography processes of semiconductor materials. During semiconductor production, precise heat treatment is critical to product performance and reliability.

Aerospace: Processing of high-performance alloys and ultra-high temperature materials that require exceptional strength and high-temperature resistance to perform in extreme environments.

Medical devices: Processing high-purity materials to ensure their quality and

performance. These materials need to be finely processed at high temperatures to

meet the high standards required for medical devices.

Key Factors When Selecting a High-Temperature Vacuum Furnace

Temperature Range

When selecting a vacuum furnace, you first need to determine the maximum temperature range it can reach. Depending on the needs of different materials, you may need furnaces that can reach different temperatures.

Brother Furnace offers high-temperature vacuum furnaces that can meet a wide range of high-temperature processing needs, ensuring that you can still obtain stable experimental results under high-temperature conditions.

Temperature Uniformity

Temperature uniformity inside the furnace is critical to the results of your experiments. A high-quality high-temperature vacuum furnace should have good temperature uniformity to avoid experimental errors caused by temperature differences.

Brother Furnace focuses on temperature uniformity inside the furnace during the design and manufacturing process and uses advanced control technology and high-precision sensors to ensure the consistency of each treatment.

Requirement of Vacuum Level

The vacuum system of a high-temperature vacuum furnace needs to reach a

specific vacuum level to ensure that the materials are not oxidized and

contaminated during the treatment process. Depending on the application

scenario, Brother Furnace can provide you with different levels of vacuum.

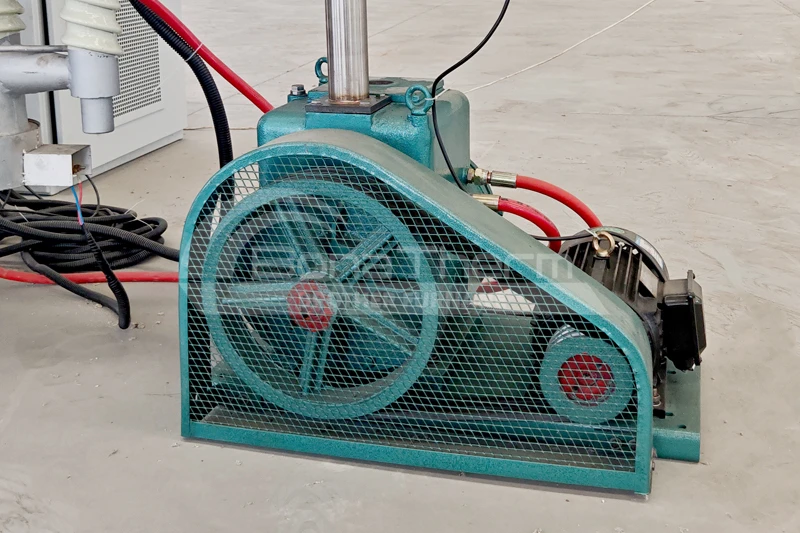

Type and Performance of Vacuum Pump

Choosing the right vacuum pump is critical to maintaining a vacuum environment in the furnace. Brother Furnace's vacuum furnaces are equipped with high-performance vacuum pump systems, which can quickly reach and maintain the required vacuum level to ensure the stability of the experimental process.

Accuracy of Control

The control system of the high-temperature vacuum furnace should be equipped with high-precision temperature and vacuum control functions to meet the needs of precision experiments. Brother Furnace adopts advanced PID control technology and provides a user-friendly interface for easy operation and monitoring.

Datalogging and Monitoring

Modern high-temperature vacuum furnaces are usually equipped with data

logging and remote monitoring functions, allowing users to track and record

experimental data in real-time, and conduct remote operation and

troubleshooting. Brother Furnace equips the high-temperature vacuum furnace with

an intelligent control system that supports data storage, remote monitoring, and

automatic alarm functions to enhance operational convenience and safety.

Materials for Furnaces

The choice of material inside the furnace directly affects the service life and performance of the furnace. High-temperature vacuum furnaces typically use high-purity, high-temperature resistant materials such as graphite and silicon carbide to withstand high temperatures and vacuum environments. Brother Furnace uses high-temperature resistant materials in the design of the furnace chamber to ensure the durability and stability of the furnace.

Design of Structure

The design of the furnace should take into account factors such as thermal expansion and furnace sealing to ensure the long-term stable operation of the furnace. Brother Furnace focuses on the structural strength and sealing performance of the furnace during the design process to ensure the reliability of the furnace in high-temperature and high-vacuum environments.

Maintenance

Maintenance and servicing of high-temperature vacuum furnaces is critical to

their long-term stable operation. Choosing a furnace that is easy to maintain

and service can reduce the failure rate and maintenance costs. High-temperature

vacuum furnaces are designed with easy maintenance in mind. At the same time,

Brother Furnace will provide you with detailed operation manuals and maintenance

guides.

After-sales Service

High-quality after-sales service can help you to solve problems in the process of use and guarantee the normal operation of the equipment. Brother Furnace provides you with comprehensive after-sales service, including equipment installation, commissioning, training and maintenance, to ensure that your equipment can run efficiently and stably.

Considerations for Choosing High-Temperature Vacuum Furnace

Determine the Requirements

When choosing a high-temperature vacuum furnace, you first need to define your application requirements, including processing temperature, vacuum, furnace volume, etc. According to the specific experimental requirements, choose the most suitable equipment model and configuration.

Consider the Budget and Cost-Effective

The price of a high-temperature vacuum furnace is usually related to its performance, configuration, and manufacturing materials. When purchasing, you need to comprehensively consider the budget and cost-effectiveness of the equipment. Brother Furnace offers a wide range of high-temperature vacuum furnaces to meet different budgets and performance needs, ensuring that you get high-quality equipment while keeping costs under control.

Brother Furnace: Professional High-Temperature Vacuum Furnace Manufacturer

Choosing the right high-temperature vacuum furnace can not only improve the

accuracy and productivity of your experiments but also provide strong support

for your research and industrial production.

As a professional manufacturer of high-temperature vacuum furnaces, Brother Furnace is committed to providing high-performance, high-quality equipment to meet your needs in a variety of applications.

If you have any questions or need to know more about our high-temperature vacuum furnaces, please feel free to contact us. Brother Furnace will be happy to provide you with professional service and support.

Brother Furnace is looking forward to cooperating with you to promote the progress of science and technology and industrial development.