How Does a Vacuum Brazing Furnace Work?

What is a vacuum brazing furnace?

The vacuum brazing furnace is a high-temperature vacuum furnace that welds metal parts together at high temperatures. At high temperatures, metal parts, and brazing materials are placed in the vacuum brazing furnace and heated simultaneously, so that the brazing materials melt and flow into the joints between the metal parts, thereby achieving the connection of the metal parts.

How does a vacuum brazing furnace work?

Vacuum brazing furnace connects metal parts and brazing materials in a high-temperature, vacuum environment, resulting in high-quality welds. Here’s a detailed breakdown of the process:

Step 1: Preparation

First, prepare the metal materials to be brazed and the brazing materials used to connect them. Make sure that these materials are clean before being placed in the vacuum brazing furnace, and that there are no contaminants on the surface that will interfere with the brazing process. Place the metal materials in the furnace and close the furnace door.

Step 2: Establishing a Vacuum Environment

Brazing needs to be done in an oxygen-free environment, so the vacuum pump of the furnace should be started and the vacuum chamber should be evacuated to the vacuum required for brazing. The purpose of this is to prevent the metal material from being oxidized by oxygen.

Step 3: Heating

Activate the heating system of the high-temperature vacuum brazing furnace and heat to the required melting point of the metal as needed. The brazing material will melt and flow into the joints between the parts. Maintain a continuous vacuum and control the heating rate to prevent a rapid drop in the vacuum.

Step 4: Cooling

Gradually lower the vacuum brazing furnace temperature after heating to solidify the brazing material and form a strong weld joint. Controlled cooling is essential to avoid thermal stress and cracking.

Step 5: Brazing is Completed

Once the furnace has cooled to a safe temperature (below 200℃), remove and inspect the welded workpiece. The brazing process is now complete.

Now that we understand how a vacuum brazing furnace works, let's explore the various industries where this technology of vacuum brazing furnace is applied.

What industries are vacuum brazing furnaces used in?

The vacuum brazing furnace has a wide range of applications. It is popular in many application fields. The following are commonly used in related industries:

|  |  |

Aerospace

Every part of the aircraft requires high-quality brazing and vacuum brazing machines can be used to weld aircraft engines, spacecraft structures, etc. Vacuum brazing furnaces can provide an oxygen-free, impurity-free welding environment to ensure the reliability and precision of the welded joints.

Car Manufacturer

Vacuum brazing oven is also suitable for welding automobile engines, chassis, body structures, and other automobile parts. The brazed workpiece has high strength and corrosion resistance.

Electronics Industry

Welding of semiconductor devices, integrated circuits, electronic components, and other precision electronic parts is also completed by furnace brazing.

Medical devices

High-Temperature Vacuum Brazing Furnace is also used for brazing metal parts of medical devices such as surgical instruments and implants.

Petrochemical

Welding of high-temperature and corrosion-resistant metal parts such as oil refining equipment, chemical containers, pipelines, etc.

Metal Processing

Aluminum vacuum brazing furnace is required for various metal workpieces, such as welding pipes, containers, pressure vessels, and brazing of aluminum products.

Precision Instrument

Welding of high-precision metal parts such as optical instruments and experimental instruments.

Given the diversity of vacuum brazing furnace applications, it is critical to choose the right vacuum brazing furnace for your business. Want to know how to choose the right vacuum brazing furnace? Please continue reading the text below.

How to choose the right vacuum brazing furnace?

Selecting the appropriate vacuum brazing furnace is crucial when you need to braze specific materials. Here are several key points to consider when making your choice

1. Identify the Type of Processing Material

Different materials require different vacuum brazing furnaces, such as furnace brazing copper, aluminum vacuum brazing furnaces, vacuum brazing furnaces for stainless steel, etc. Ensure the furnace is compatible with the material you will be brazing.

2. Determine the Size of the Furnace Chamber

Choose the vacuum brazing furnace that can accommodate the size of your workpiece. Ensure there is enough space in the furnace for brazing operations.

3. Temperature Range and Control

Verify that the furnace's maximum temperature meets the requirements of your brazing material. Different heating elements have varying operating temperatures, so select accordingly.

4. Vacuum Level

Depending on the brazing material, select a furnace that can achieve the required vacuum level. Generally, a higher vacuum degree results in better brazing outcomes.

5. Material of Furnace Chamber

The vacuum brazing machine chamber material should withstand high temperatures and vacuum environments and possess good thermal conductivity. Common materials include molybdenum, stainless steel, etc.

6. Cost and Budget

Choose cost-effective equipment that fits your budget, but does not compromise on quality and performance. Investing in a high-quality vacuum brazing furnace can enhance production efficiency and product quality.

7. Maintenance and Service

Opt for a vacuum brazing furnace that is easy to maintain. Select suppliers with good reputations and comprehensive after-sales service to ensure timely technical support and maintenance during use.

After reading this text, you have the answer to how to choose a vacuum brazing furnace. If you want to know more about the details of the vacuum brazing furnace, please browse the following information about the Brother Furnace vacuum brazing furnace. You will get more useful information.

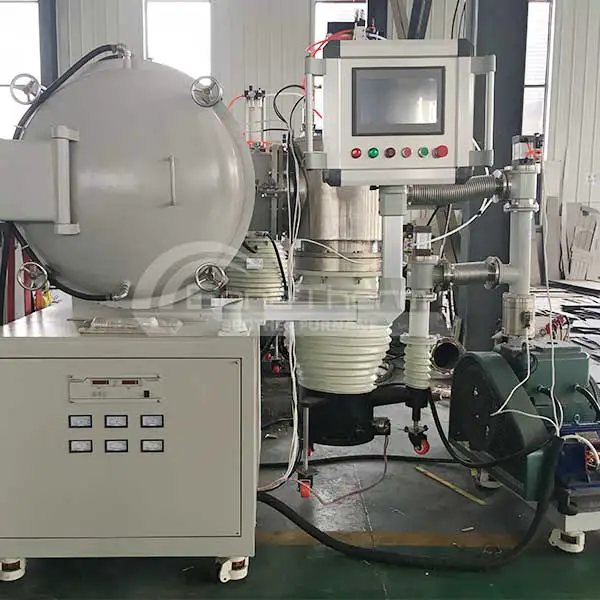

Explore Brother Furnace's Vacuum Brazing Furnace

As a renowned high-temperature furnace manufacturer, Brother Furnace has been providing 1,000+ different vacuum furnaces to customers worldwide since its establishment in 2008. Our main vacuum brazing furnaces include vacuum brazing furnace (molybdenum thermal field), vacuum brazing furnace (heat-resistant steel hot field), and vacuum cutting-tools brazing furnace. If you have any needs, please feel free to contact us!

The difference between three vacuum brazing furnaces

Next, I will introduce the vacuum brazing furnace from four angles: furnace chamber material, maximum operating temperature, materials suitable for processing, and parameters.

Vacuum Brazing Furnace ( molybdenum thermal field )

Furnace chamber: The furnace chamber of vacuum brazing molybdenum foil furnace mainly adopts molybdenum foil metal furnace and the heating element is molybdenum strip heating.

Max temperature: The operating temperature of the Vacuum Brazing Furnace (molybdenum thermal field) can reach up to 1350℃.

Materials suitable for brazing: The vacuum brazing molybdenum foil furnace is mainly suitable for workpieces with silver, copper, and nickel as brazing flux. Due to the high vacuum degree and high temperature of the vacuum molybdenum foil brazing furnace, it can also be used for the brazing and sintering of other workpieces.

Technical Parameters of vacuum brazing molybdenum foil furnace

model | Heating area (width*height*depth) ( mm ) | Temperature(℃) | Power ( kW ) | Power supply ( V ) |

|---|---|---|---|---|

BR-QHM-223 | 200*200*300 | 1350 | 34 | 380 |

BR-QHM-334 | 300*300*400 | 1350 | 60 | 380 |

BR-QHM-446 | 400*400*600 | 1350 | 98 | 380 |

BR-QHM-557 | 500*500*700 | 1350 | 132 | 380 |

BR-QHM-669 | 600*600*900 | 1350 | 180 | 380 |

Vacuum Brazing Furnace ( heat-resistant steel hot field )

Furnace chamber: The furnace chamber material of Vacuum Brazing Furnace ( heat-resistant steel hot field ) is mainly stainless steel and electric heating alloy tube.

Max temperature: Vacuum Brazing Furnace (heat-resistant steel hot field) maximum operating temperature 750℃.

Suitable materials for brazing: Vacuum Brazing Furnace (Heat-Resistant Steel Hot Field) is particularly well-suited for vacuum brazing of low melting point workpieces like aluminum alloys, it is also versatile enough to handle a range of other materials. This furnace can effectively braze various metals, including copper alloys, stainless steel, and certain types of titanium alloys.

Technical parameters of Vacuum Brazing Furnace ( heat-resistant steel hot field )

model | Heating area (width*height*depth) ( mm ) | Temperature(℃) | Power ( kW ) | Power supply ( V ) |

|---|---|---|---|---|

BR-QHS-223 | 200*200*300 | 750 | 12 | 380 |

BR-QHS-334 | 300*300*400 | 750 | twenty one | 380 |

BR-QHS-446 | 400*400*600 | 750 | 34 | 380 |

BR-QHS-557 | 500*500*700 | 750 | 46 | 380 |

BR-QHS-669 | 600*600*900 | 750 | 64 | 380 |

Vacuum Cutting-Tools Brazing Furnace

Furnace chamber: Vacuum cutting-tools brazing furnace chamber material is mainly Ceramic fiber, ensuring excellent insulation properties and temperature uniformity during the brazing process, facilitating precise and efficient brazing of cutting tools and other workpieces.

Max temperature: High-temperature vacuum cutting-tools brazing furnace can operate at temperatures up to 1200℃.

Suitable materials for brazing: Vacuum tool brazing furnace is suitable for brazing of smaller size superhard materials, such as carbide tools (PCD tools, PCBN tools, CVD tools.

Technical parameters of vacuum tool brazing furnace

model | Maximum temperature (℃) | Heating zone size (diameter*height) ( mm ) | Overall dimensions (mm) | Power (kW) | Thermocouple |

|---|---|---|---|---|---|

BR-200BF | 1200 | Φ 200x400 | 1235x1150x750 | 8 | K type |

Advantages of Brother Furnace Vacuum Brazing Furnace

1. Vacuum brazing furnaces ensure temperature uniformity, resulting in consistent brazing quality of workpieces

2. Brother Furnace's vacuum brazing furnaces offer a wide range of welding materials, including high melting point metal materials.

3. Our vacuum brazing machines produce minimal polluting gas emissions and carbon emissions during the process of welding metals such as aluminum and stainless steel, contributing to environmental sustainability.

4. The vacuum environment of our brazing furnaces prevents oxidation and contamination, maintaining the cleanliness of the brazing materials.

5. Brother Furnace's vacuum brazing furnaces feature full PLC control and a 10-inch HD touch screen.

6. Our high-temperature vacuum brazing furnaces have the high production capacity and can weld more than 600 parts in one operation.

Are you looking for a suitable vacuum brazing furnace for your materials?

Please don't miss Brother Furnace. We have been in the vacuum furnace industry for nearly 20 years. Our vacuum brazing furnaces have high-quality heating systems and vacuum systems to help you design and obtain the perfect brazing solution and ensure that the brazed materials meet your expectations.

In addition, we also provide customized services and problem-solving for customers.

If you have any different needs, or you don’t know how to choose a suitable vacuum brazing furnace, please submit the form and leave your needs. We will reply to you within an hour.