High Temp Sealed Quench Furnaces: The Ultimate Guide for Industrial Heat Treatment Buyers

In the realm of industrial heat treatment, high-temperature sealed quench furnaces play a pivotal role. These advanced pieces of equipment are designed to

subject materials to controlled heating and rapid cooling processes,

transforming their metallurgical properties.

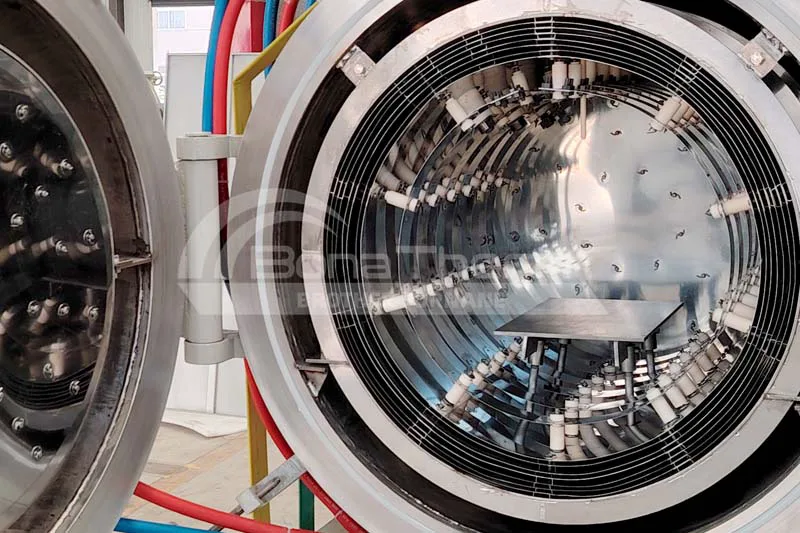

A sealed quench furnace is essentially a specialized furnace that operates under a vacuum or inert gas atmosphere to prevent oxidation and ensure precise temperature control during the quenching phase.

The significance of these furnaces in modern manufacturing processes cannot be overstated. They are integral to achieving high-quality, reliable outcomes in a wide range of industries.

From automotive manufacturing to aerospace components, the ability to precisely control the heating and quenching processes is crucial for optimizing material properties such as hardness, toughness, and corrosion resistance.

Key Features of High-Temp Sealed Quench Furnaces

Controlled Atmosphere Technology: One of the defining features of a high-temperature sealed quench furnace is its ability to maintain a controlled atmosphere. This can be achieved through the use of inert gases or vacuum conditions, which prevent the material from reacting with oxygen during the heat treatment process. This is particularly important for materials that are susceptible to oxidation, such as stainless steel and tool steel.

Precise Temperature Regulation: Another key aspect is precision temperature

control. The furnaces from Brother Furnace utilize advanced thermocouples and

control systems to maintain temperatures within tight tolerances, ensuring

consistent and repeatable results. This precision is essential for achieving the

desired metallurgical properties in the treated materials.

Integrated Quenching Systems: The quenching process is critical in determining the final properties of the material. High-temperature sealed quench furnaces are equipped with integrated quenching systems that rapidly cool the material after heating, locking in the desired microstructure. These systems can utilize various quenching media, such as oil, water, or inert gases, depending on the specific requirements of the application.

Automated Process Control: To further enhance efficiency and consistency, our high-temp sealed quench furnaces are equipped with automated process control systems. These systems can monitor and adjust the heating and quenching parameters in real time, ensuring optimal performance and minimizing human error.

Energy-Efficient Design: In today's world, energy efficiency is a top priority. Many modern high-temperature sealed quench furnaces are designed with energy-saving features, such as insulation materials and heat recovery systems, to minimize energy consumption and reduce operating costs.

Benefits of Using High-Temp Sealed Quench Furnaces

The benefits of using high-temperature sealed quench furnaces are numerous and span across various aspects of industrial manufacturing.

Enhanced Metallurgical Properties: By precisely controlling the heating and

quenching processes, these furnaces can significantly improve the metallurgical

properties of the treated materials. This includes increased hardness,

toughness, and corrosion resistance, which are critical for applications in

demanding environments.

Improved Process Efficiency and Throughput: Automated process control and precise temperature regulation enable faster and more consistent heat treatment cycles, leading to improved process efficiency and increased throughput. This is particularly beneficial in high-volume manufacturing environments.

Consistent and Repeatable Results: The precision and control offered by high-temperature sealed quench furnaces ensure consistent and repeatable results, reducing the variability in material properties and enhancing product quality.

Reduced Operating Costs: Energy-efficient design and optimized process parameters can lead to significant reductions in operating costs, making these furnaces a cost-effective solution for industrial heat treatment needs.

Minimized Environmental Impact: By reducing energy consumption and minimizing waste,Brother Furnace’s high-temperature sealed quench furnaces contribute to a more sustainable manufacturing process. This is increasingly important in today's environmentally conscious world.

Applications Across Industries

The versatility of high temp sealed quench furnaces makes them suitable for a wide range of industrial applications.

Automotive Manufacturing: In the automotive industry, these furnaces are used

for heat-treating components such as gears, shafts, and bearings to enhance

their durability and performance. The ability to achieve precise hardness and

toughness levels is crucial for ensuring the reliability and safety of

automotive components.

Aerospace Components: Aerospace quenching technology demands the highest levels of precision and control. High-temperature sealed quench furnaces are essential for treating materials like titanium and nickel alloys, which are critical for the performance of aerospace components.

General Industrial Machinery: These furnaces are also used in the manufacture of general industrial machinery components, such as gears, shafts, and bearings, to improve their durability and performance.

Medical Device Manufacturing: In the medical device industry, the precision and control offered by high-temperature sealed quench furnaces are essential for treating materials used in implants and surgical instruments, ensuring their safety and effectiveness.

Considerations for You

When considering the purchase of high-temperature sealed quench furnaces, there are several factors that potential buyers should take into account.

Assessing Capacity Requirements: The first step is to determine the capacity

requirements for the furnace. This includes considering the size and weight of

the materials that will be treated, as well as the throughput needed to meet

production demands.

Evaluating Temperature Range and Uniformity: The temperature range and uniformity are critical factors in determining the effectiveness of the heat treatment process.

Analyzing Quenching Medium Options: The choice of quenching medium can have a significant impact on the final properties of the treated material. You should consider the available quenching options, such as oil, gas, or inert gases, and select the one that best meets their needs.

Considering Automation and Control Systems: Automated process control systems can significantly enhance the efficiency and consistency of the heat treatment process. You’d better assess the available control systems and determine which one offers the best combination of functionality and ease of use.

Examining Vendor Reputation and After-Sales Support: Finally, it’s important

to carefully consider the reputation of the vendor and the level of after-sales

support offered. Choosing a reputable manufacturer like Brother Furnace with a

strong commitment to customer service will ensure a smooth purchase and ongoing

support for the furnace.

Conclusion

In conclusion, high-temperature sealed quench furnaces are indispensable pieces of equipment in modern industrial heat treatment processes. Their ability to precisely control the heating and quenching processes ensures consistent and repeatable results, enhancing the metallurgical properties of treated materials.

The benefits of using these furnaces are numerous, including improved process efficiency, reduced operating costs, and minimized environmental impact.

As a leading manufacturer of high-temperature sealed quench furnaces, Brother Furnace is committed to providing high-quality, reliable equipment that meets the needs of industrial users.

We invite you to explore our range of products and discover how our furnaces can enhance your manufacturing processes.

With our expertise and commitment to excellence, Brother Furnace is confident that we can provide the perfect solution for your industrial heat treatment needs.