A Swedish Carbide Cutting Tool Company Purchases a Carbide Vacuum Sintering Furnace

Recently, a prominent carbide-cutting tool company in Sweden invested

strategically in a vacuum sintering furnace for carbide from Brother Furnace. As

a manufacturer specializing in carbide vacuum sintering furnaces, we proudly to

support industry leaders in elevating their production capabilities.

In the highly competitive world of carbide tool manufacturing, technological innovation, and process refinement are key to maintaining a market edge.

This case study not only highlights the exceptional results our client experienced but also underscores the critical role that advanced sintering technology plays in improving quality, efficiency, and competitiveness.

Our Client: A Global Leader in Carbide Cutting Tools

Based in Sweden, this client is a well-known manufacturer of cemented carbide cutting tools used across a wide range of industries, including aerospace, automotive, and precision engineering.

Their tools are recognized for their durability and cutting precision, making

them a trusted supplier for high-demand sectors that require top-tier carbide

products. The company’s commitment to innovation and excellence in manufacturing

has driven its decision to continually upgrade its production processes.

With increasing global demand for their products, the client sought to invest in a state-of-the-art high-temperature vacuum furnace that would allow them to improve both production efficiency and product quality.

They needed equipment that could meet their stringent specifications for sintering carbide materials, ensuring maximum hardness, toughness, and wear resistance—all critical attributes for the demanding applications their tools are used.

The Challenge: Optimizing Carbide Sintering

Before approaching us, the client faced challenges with their existing sintering processes. Their older equipment, while functional, lacked the precision and consistency needed to achieve the high-quality results required in modern carbide manufacturing.

The client’s previous furnace struggled to maintain the ideal temperature and vacuum conditions necessary for producing high-performance cemented carbide tools. Additionally, the furnace's energy consumption was proving costly, leading to inefficiencies in both time and operational costs.

Our client needed a solution that would enable them to optimize their sintering process and scale production without sacrificing quality. The ideal furnace would need to provide precise control over the sintering environment, including temperature, pressure, and atmosphere, to ensure that the carbide tools would meet their exacting standards.

Our Solution: The Cemented Carbide Sintering Furnace

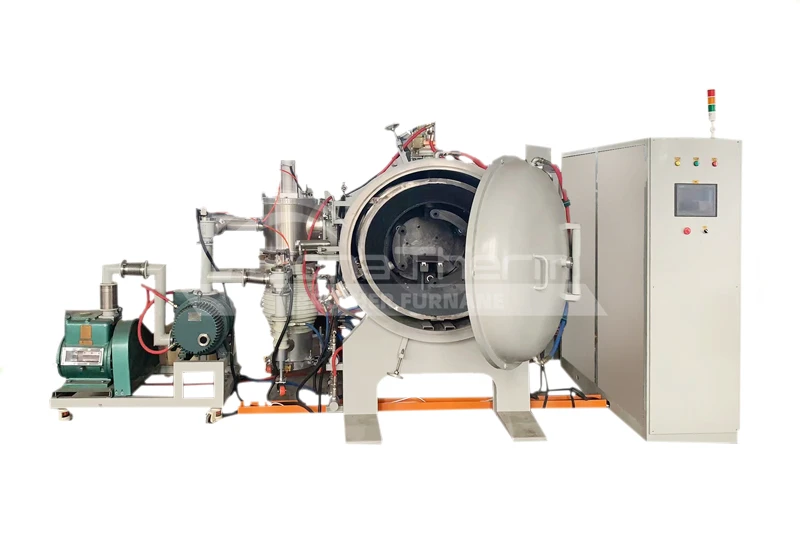

After thoroughly understanding the client’s requirements, we recommended our

carbide vacuum sintering furnace, specifically designed for sintering cemented

carbide materials under vacuum conditions. This furnace operates at high

temperatures—up to 2200°C—while maintaining a stable vacuum environment, making

it ideal for producing carbide tools with superior hardness and strength.

Key features of our vacuum furnace for carbide processing include:

● Precise Temperature Control: The furnace is equipped with advanced thermocouples and a control system that allows for accurate temperature adjustments. This is essential for preventing defects such as grain growth, which can compromise the mechanical properties of carbide tools.

● Vacuum and Atmosphere Control: The furnace maintains a deep vacuum level to remove any impurities and prevent oxidation during the sintering process. In some cases, an inert gas atmosphere can be introduced to further protect the material from contamination.

● Energy Efficiency: With energy-efficient heating elements and a highly insulated chamber, the furnace consumes significantly less power than older models, reducing operational costs while increasing throughput.

These features ensure that the sintering process is conducted under optimal conditions, resulting in tools that have a uniform microstructure, higher density, and improved wear resistance.

Installation and Integration

Upon finalizing the purchase, the team from Brother Furnace worked closely

with the client to ensure a seamless installation process. The furnace was

integrated into their existing production line, with minimal disruption to

ongoing operations. Our engineers provided comprehensive training to the

client’s technical team, ensuring they were equipped to operate and maintain the

furnace effectively.

Once operational, the high-temperature vacuum furnace quickly demonstrated its value. The client reported that the furnace’s advanced controls allowed them to achieve better consistency in their sintering process. The tools produced in the new furnace had more uniform grain structures, translating to improved performance in real-world applications. Additionally, the furnace’s automated systems reduced the manual labor required for temperature and pressure adjustments, saving the company both time and money.

Client Feedback: Transforming Production Efficiency

The Swedish company provided us with glowing feedback about the furnace’s performance. One of the first improvements they noticed was the enhanced uniformity in their carbide tools’ mechanical properties, particularly hardness and toughness. With the cemented carbide sintering furnace, they were able to produce tools with greater resistance to wear and deformation, which is critical for their customers in high-stress industries.

Another significant advantage was the reduction in energy consumption. The furnace’s efficient design allowed the company to cut down on its energy costs while increasing overall production capacity. This was especially important as the company was expanding its operations to meet growing market demand.

Furthermore, the vacuum sintering furnace for carbide helped the client

shorten their production cycle times. With the furnace’s rapid heating and

cooling capabilities, they were able to accelerate the sintering process without

compromising on quality. This has enabled the company to fulfill customer orders

more quickly, improving its competitiveness in the global market.

Impact on the Client’s Business

Since the installation of the vacuum furnace for carbide processing, the Swedish company has seen significant improvements in both the quality of its products and the efficiency of its operations. Their carbide tools, which are now sintered under more controlled conditions, offer better performance and longer lifespans, increasing customer satisfaction.

The energy savings and improved throughput have also had a positive impact on the company’s bottom line. With lower operational costs and higher production volumes, the company has been able to expand its product offerings and enter new markets, further strengthening its position as a leader in the carbide-cutting tool industry.

Conclusion: The Value of Advanced Sintering Technology of Brother Furnace

This case study illustrates the transformative impact that a carbide vacuum sintering furnace can have on a manufacturer’s production process.

Our partnership with this Swedish carbide cutting-tool company is a prime

example of how modern sintering technology can help companies improve product

quality, reduce costs, and stay competitive in an increasingly demanding

market.

For manufacturers looking to optimize their carbide production processes, our vacuum sintering furnaces for carbide offer unparalleled precision, efficiency, and durability.

Brother Furnace is committed to helping our clients achieve their goals by providing cutting-edge technology and unmatched customer support.

Whether you are looking to upgrade your sintering equipment or expand your production capabilities, our cemented carbide sintering furnace is designed to meet your needs and exceed your expectations.