A Myanmar Electronic Component Manufacturer Purchases a Vacuum Melting Furnace from Brother Furnace

With the rapid changes in global manufacturing, the demand for high-tech

equipment is increasing in various industries, especially in high-precision and

high-performance electronic component production. Myanmar, as an important

manufacturing base in Southeast Asia, is gradually emerging as an important

market for electronic component production.

Brother Furnace, a leading manufacturer of vacuum melting furnaces, is honored to cooperate with this top electronic component manufacturer in Myanmar by providing a newly developed vacuum melting furnace.

After years of development, this Myanmar electronic component manufacturer has grown to become a leading electronic component supplier in Myanmar. This company is mainly engaged in the research and development and production of integrated circuits, capacitors, sensors, and other electronic products, which are widely used in communications, automotive electronics, consumer electronics, and other fields.

With the development of the global electronic products market, the company has become one of the leading suppliers of electronic components in Myanmar.

In searching for efficient and sophisticated melting equipment, the company conducted extensive market research and comprehensively compared the technical specifications, product performance, and service quality of several suppliers. In the end, they chose Brother Furnace's high-temperature vacuum melting furnace.

Brother Furnace's vacuum melting furnace not only has industry-leading

technical advantages, but also meets their strict requirements for high-purity

metals.

Features of Vacuum Melting Furnaces

Brother Furnace's vacuum melting furnace has the following significant features that make it stand out in the market:

Advanced Heating Principle

The vacuum melting furnace adopts medium frequency induction heating technology, combined with IGBT or KGPS medium frequency power supply, which is capable of efficient melting at temperatures up to 2100℃.

Medium-frequency induction heating technology not only ensures uniform heating of the metal during the melting process but also effectively improves melting efficiency and metal purity.

This technology performs particularly well with demanding materials such as

nickel-based alloys and precision alloys.

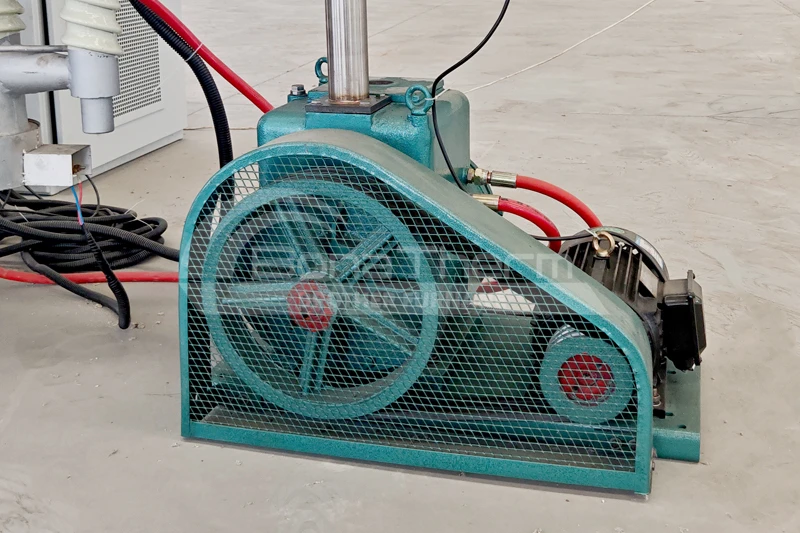

Highly Efficient Vacuum System

The vacuum induction melting furnace is equipped with a multi-stage vacuum pumping system including mechanical, Roots, and diffusion pumps to achieve an ultimate vacuum of 6x10^-3 Pa. This system effectively removes gases from the furnace and creates a high-purity vacuum environment that ensures the stability of the process and the quality of the metal.

Flexible Charging System

The alloy charger fitted as standard allows the gradual charging of the molten metal in the crucible by turning a handwheel. A secondary dosing system is also available as an option: this allows for continuous dosing in a vacuum environment and meets the requirements of different melting processes. This flexible charging method greatly improves the flexibility and efficiency of production.

Convenient for Observation and Maintenance

The furnace cover is fitted with an observation window, which allows the user to observe the working status of the furnace in real time. The viewing window is equipped with a shield to prevent contamination of the glass by metal vapor deposits.

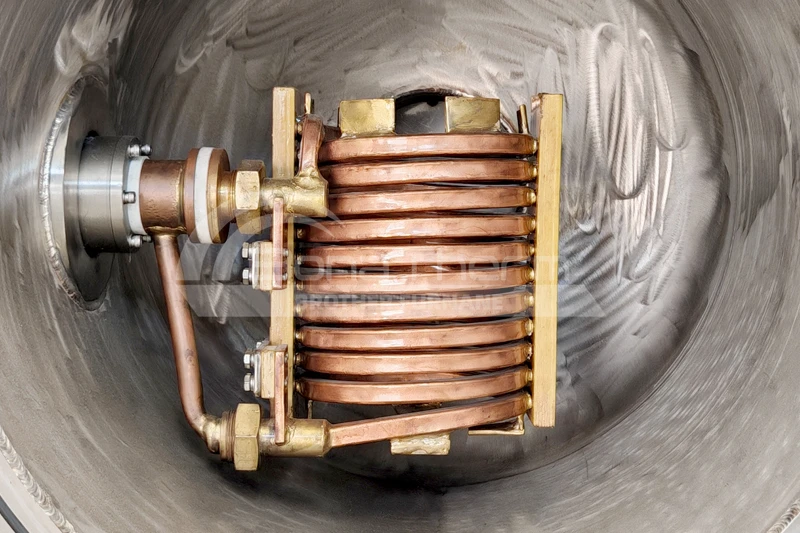

Efficient Inductor

The inductor for melting metal is located inside the furnace housing, is made

of rectangular copper tubes, and is fixed to the electrodes by means of two

connectors. The inductor can be equipped with a pre-sintered molded crucible

inside or with a pounded crucible on the inner wall to accommodate different

melting metals, thus meeting the needs of different application scenarios.

Customer Feedback: Unexpected Performance

Since using Brother Furnace's vacuum melting furnaces, customers have highly evaluated the performance of the equipment.

Excellent melting effect: Brother Furnace's vacuum melting furnace adopts the principle of intermediate frequency induction heating, combined with IGBT or KGPS intermediate frequency power supply, and is capable of melting at high temperatures of up to 2100°C. This advanced heating technology ensures the purity of the metal in the melting process. This advanced heating technology ensures the purity of the metal during the melting process and greatly improves the quality of the metal. Customers report that this high-purity metal significantly improves the performance and stability of their electronic components and meets their stringent standards for high-quality products.

Efficient production capacity: The vacuum melting furnace is equipped with a

highly efficient vacuum system, including mechanical, Roots, and diffusion

pumps, with an ultimate vacuum of 6x10^-3 Pa. The high efficiency of this system

allows the machine to complete the melting process in a short time, which

greatly improves production efficiency. The customers especially pointed out

that the high performance of the equipment not only improves the production

capacity, but also helps them to maintain a competitive edge in the highly

competitive market.

Excellent after-sales service: The customer particularly praised Brother Furnace's service team for their proactive attitude and professional ability in solving equipment problems and optimizing the production process. Brother Furnace's technical team excels in the installation and commissioning of the equipment as well as in the operation training, which provides a strong guarantee for the customer's production operation.

Brother Furnace Looks Forward to Working with You

Brother Furnace has once again proved its leadership in vacuum melting technology through successful cooperation with Myanmar electronic component manufacturers. With its advanced heating principle, highly efficient vacuum system, and intelligent operation interface, Brother Furnace's vacuum induction melting furnace has successfully met the customer's demand for high-purity metals and significantly improved their production capacity and product quality. This not only verifies the excellent performance of Brother Furnace's products but also further strengthens the leading position of Brother Furnace in the global market.

As a professional manufacturer of vacuum melting furnaces, Brother Furnace will continue to dedicate itself to technological innovation and service optimization, striving to provide customers around the world with more efficient and reliable melting equipment.

If you are looking for a vacuum melting furnace that can improve your productivity and product quality, please feel free to contact us.

Brother Furnace will be dedicated to providing you with the best quality products and services to help your production development and market competitiveness.