A German Automotive Parts Manufacturer Purchases a Vacuum Brazing Furnace

In the global industrial market, the demand for high-precision and

high-efficiency equipment in the manufacturing industry continues to grow,

especially in the field of automotive parts manufacturing.

As a leading manufacturer of vacuum brazing furnaces, Brother Furnace is honored to work with a top international company to provide an innovative and high-quality solution for this automotive parts manufacturer.

Founded in the 20th century, this automotive parts manufacturer in Germany is a globally recognized supplier of automotive components. The company specializes in the development and production of high-performance automotive parts, especially in the engine components and drive train components with a deep accumulation of technology and market influence.

With the rapid technological development of the automotive industry and the continuous upgrading of market demand, the company recognizes the importance of updating its production equipment to maintain its leading position in technological innovation and market competition.

After extensive market research and equipment evaluation, they finally chose

Brother Furnace's vacuum brazing furnace to meet their production needs.

Why Do People Choose Brother Furnace?

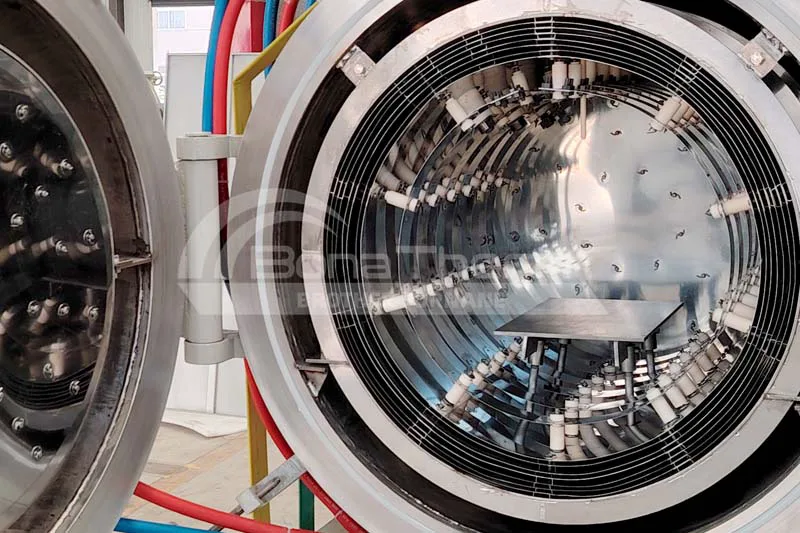

High Vacuum

Brother Furnace's vacuum brazing furnaces are capable of achieving extremely high vacuum levels to ensure material purity during the brazing process. This high vacuum not only prevents oxidizing reactions but also eliminates possible gas disturbances during the brazing process, guaranteeing the highest standards of brazing quality.

The extremely low residual gas content allows the material to remain stable during the welding process, thus increasing the strength and durability of the welded joint.

Precise Temperature Control System

Vacuum welding furnaces are equipped with an advanced temperature control system that precisely controls temperature fluctuations during the welding process. Brother Furnace utilizes high-precision temperature sensors and controllers to ensure that the temperature control at every step of the welding process is within the optimal range.

Precise temperature control not only ensures the stability of the welding process but also improves the consistency of each product and reduces the impact of temperature fluctuations on welding quality.

Uniform Heating Technology

The vacuum brazing furnace adopts innovative heating technology to ensure uniform heat distribution inside the furnace. This uniform heating effect not only improves welding stability but also effectively avoids welding defects caused by temperature differences.

This heating method maintains consistent temperature conditions throughout

the entire welding process, thereby improving the quality and consistency of the

welded joints.

Design for Energy Saving

Brother Furnace pays special attention to the energy-saving and environmental protection performance of the machine and has designed a highly efficient energy utilization system that significantly reduces energy consumption.

By optimizing the furnace structure and the design of the heating system, the high vacuum brazing furnace is able to maintain a consistent temperature condition throughout the entire welding process, thus improving the quality and consistency of the welded joints.

In addition, Brother Furnace's vacuum brazing furnaces comply with the latest environmental regulations, reducing emissions and energy waste in the production process and meeting the requirements of sustainable development in modern industry.

Intelligent Operating System

The vacuum welding furnace is equipped with an intelligent control system with an intuitive and easy-to-use operation interface. You can easily set and adjust the welding parameters through the touch screen and monitor the running status of the equipment in real-time.

Intelligent operation system not only improves the operation convenience of

the equipment but also reduce human errors and improve the stability of the

production process.

High Reliability and Durability

Brother Furnace's vacuum brazing furnaces use high-quality materials and advanced manufacturing processes to ensure the long-term reliability and durability of the equipment.

High-temperature and corrosion-resistant materials allow the equipment to perform well even after long periods of high workload. After rigorous quality inspection and durability testing, Brother Furnace's brazing furnaces are able to operate stably in a variety of complex production environments, providing customers with a guarantee of long-lasting performance.

High Praise from Customers

The German automotive parts manufacturer has now put the vacuum welding furnace from Brother Furnace into operation. They are highly impressed by the performance of the equipment.

First of all, the precision brazing furnace has significantly improved the overall efficiency of the production line.

Customers have reported a significant increase in welding speeds and a significant reduction in line downtime with the new equipment. This improvement has not only increased production capacity but also helped the company to reduce production costs, making it more competitive in the market.

The customer has also seen significant improvements in product quality. By

using the brazing furnace, they found that the welding quality of automotive

parts was greatly improved. The high vacuum and precise temperature control

technology ensured the strength and durability of the welded joints, allowing

their products to gain higher recognition in the market.

The customer specifically mentioned that this enhancement in weld quality has enabled them to better meet the high standards of their customers and improve the competitiveness of their products in the market.

In terms of operation, the customer also spoke highly of the furnace's feature of easy operation. The brazing furnace's operator interface is intuitive and easy to use, and the introduction of an intelligent control system reduces human error and improves the stability of the production process.

In addition, the customer also said that the simplicity of the operation of the equipment greatly reduces the training time of the staff and further improves the production efficiency.

Brother Furnace: a Professional Brazing Furnace Manufacturer

Brother Furnace has successfully met the customer's high demands for

productivity and product quality due to its excellent performance and

reliability. This success story not only demonstrates Brother Furnace's

technical strength as a manufacturer but also further strengthens its leading

position in the industry.

As a company specializing in precision brazing furnace manufacturing, Brother Furnace is always committed to providing customers with the highest quality products and services.

Whether it's automotive parts manufacturing or other industrial applications, Brother Furnace's products meet a variety of needs and help our customers stand out in a competitive marketplace.

If you are interested in Brother Furnace's vacuum brazing furnace or other related equipment, please feel free to contact us.

Brother Furnace is looking forward to cooperating with you to promote the development and progress of industrial technology.