6 Tips for Maintaining the Performance of Your Vacuum Furnace

As a professional vacuum furnace manufacturer, Brother Furnace understands

the critical role vacuum furnaces play in modern industry.

Vacuum furnaces are widely used in metal heat treatment, ceramic sintering, glass manufacturing, and other fields due to their ability to provide extremely high-temperature control and a pure processing environment. Due to their higher costs and more complex operating systems, it is especially important to ensure optimal performance and long-term stability of vacuum furnaces.

In this article, we will provide you with six practical tips to help you

effectively maintain your vacuum furnace, improve its efficiency, and extend the

service life of the equipment.

1. Regularly Check the Sealing of the Vacuum System

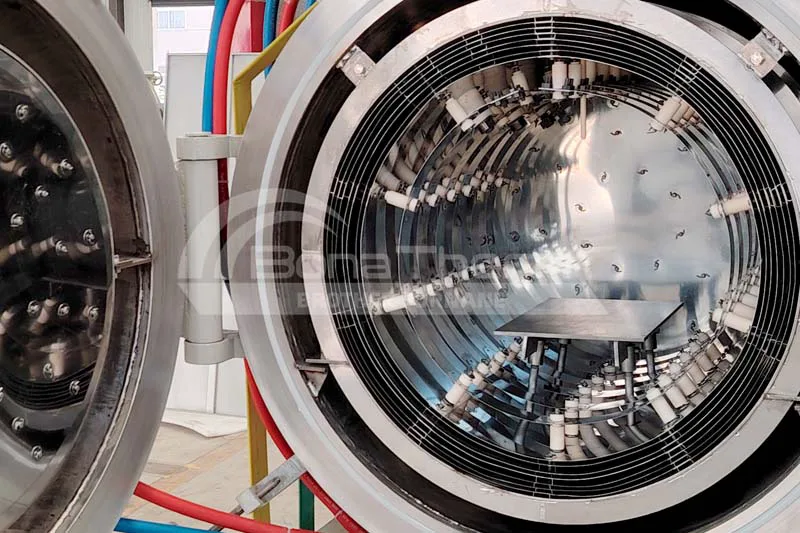

The core of a vacuum furnace is its ability to maintain a stable vacuum environment. The sealing of the vacuum system directly affects the vacuum level and operational stability of the furnace. The sealing system includes the sealing strips of the furnace door, various valves, and joints, and these parts must be kept in good sealing condition to prevent the leakage of air or other gases.

Regularly checking the integrity and sealing effectiveness of these sealing components, using high-performance sealants and seal-checking tools, ensures that any small leaks can be detected and repaired promptly.

Vacuum system maintenance not only prevents gas contamination in the production process but also avoids energy wastage due to vacuum leakage. The vacuum furnaces manufactured by Brother Furnace are equipped with advanced sealing systems and high-precision vacuum monitoring instruments, which are designed not only to ensure excellent sealing results but also to provide real-time feedback to help you maintain an optimal production environment.

2. Keep the Furnace Clean

A clean environment inside the furnace is critical to the performance of the vacuum furnace. High-temperature operations and chemical reactions produce residues and contaminants that not only affect heating efficiency but can also lead to equipment failure. Regular cleaning of residues and dirt inside the furnace to ensure a clean environment can effectively improve the efficiency of the equipment and reduce the probability of malfunction.

During the cleaning process, it is recommended to use special cleaning tools

and mild detergents to avoid damage to the Furnace Structure. Especially after

high-temperature sintering or other high-temperature operations, a thorough

cleaning should be carried out. The design of Brother Furnace's vacuum furnaces

focuses on easy cleaning of the internal structure.

The use of high-temperature-resistant materials and removable components allows you to easily carry out deep cleaning and ensures long-lasting and stable operation of the equipment.

3. Monitoring Temperature and Pressure

The stable operation of a vacuum furnace depends on precise control of temperature and pressure. Continuously monitoring the temperature and pressure of your vacuum furnace allows you to identify and solve potential problems in a timely manner. Vacuum furnaces manufactured by Brother Furnace are equipped with high-precision temperature and pressure sensors, which can provide real-time feedback on the operating status of the equipment, as well as data logging and analysis functions.

As a professional vacuum furnace manufacturer, Brother Furnace also pays attention to protecting the safety of customers when using the product. Brother Furnace has installed an automatic alarm system for vacuum furnaces, which can alert you when the temperature or pressure is out of the set range so that you can take prompt measures to make adjustments.

These systems not only help you to control your production process but also enable you to perform trend analysis, predict potential problems and further optimize your production operations.

4. Regular Maintenance and Overhaul

The long-term stable operation of the vacuum furnace requires regular and systematic maintenance and overhaul. The power supply system, heating elements, control system, etc. should be inspected and serviced according to the recommended cycles. Brother Furnace recommends that you develop a detailed maintenance program and follow the maintenance guidelines in the manuals provided by Brother Furnace to prevent potential failures.

For critical components, such as heating elements, it is recommended to have

them professionally inspected and serviced at regular intervals. Brother Furnace

provides you with comprehensive after-sales service and technical support to

ensure that your equipment is always in the best condition.

You can also contact us if you have any problems that are difficult to solve during the use of your equipment. Brother Furnace technicians can provide you with maintenance services to help you solve any problems and to ensure that your vacuum furnace can run stably for a long time.

5. Avoid Overload

The overloading of a vacuum furnace will lead to excessive wear and tear of the machine, which will shorten its service life. On the other hand, overloaded operation of the furnace will not only lead to increased energy consumption but may also affect the quality of the product and even cause equipment failure.

To ensure the long-term stability and high performance of the equipment, it is crucial to ensure that the vacuum furnace operates within its rated load range.

The vacuum furnaces supplied by Brother Furnace are designed and rigorously tested to meet a wide range of process requirements and are capable of stable operation under high load conditions.

6. Maintain Proper Calibration of Equipment

Accurate calibration of high-temperature vacuum furnaces is essential to

ensure production quality. Regularly checking and calibrating the parameters of

the vacuum furnace, such as temperature, pressure, and vacuum, ensures

consistency and stability of the production process. It is recommended that you

use certified calibration equipment and follow the standards provided by Brother

Furnace to ensure the accuracy and reliability of your equipment.

Brother Furnace: A Professional Vacuum Furnace Manufacturer

Regular maintenance is very important for vacuum furnaces. It not only significantly improves the operational efficiency and stability of the equipment, ensuring that the expected process requirements are met during production, but also effectively reduces production delays and cost increases due to downtime.

Careful maintenance, such as regular cleaning of the furnace chamber, checking and replacing worn seals, and calibrating the control system, can greatly extend the service life of a vacuum furnace and keep it in excellent working condition for a longer period of time.

This is undoubtedly the key to enhancing competitiveness for enterprises relying on high-end equipment for precision manufacturing.

As a professional manufacturer in the field of vacuum furnaces for many years, Brother Furnace understands the importance of high-quality products and comprehensive service support for customers.

Therefore, Brother Furnace is not only committed to the development and

production of leading technology, and excellent performance of the vacuum

furnace, but also put customer service in the first place, to provide a full

range of guidance and support from installation and commissioning to routine

maintenance.

Brother Furnace is convinced that through our unremitting efforts, we can help customers to better manage their vacuum furnaces, so that it can maximize its effectiveness in the production process and create greater value for the enterprise.

By choosing Brother Furnace, you will have a manufacturing partner that is not only technologically advanced but also excels in real-world applications. Let's work together for a better future.